Founded in 1997, Zhejiang Bolei Coatings Co., Ltd. is a subsidiary of Bolei Industrial Group, with multiple subsidiaries engaged in coatings manufacturing, construction services, new material development, and international trade.

As a professional paint manufacturer based in China, we specialize in anti-corrosion coatings, fireproof coatings, emulsion paints, epoxy floor paints, and JS waterproof paints, widely applied in both industrial and construction sectors.

With advanced production facilities, a strict quality control system, and a stable raw material supply chain, we deliver high-quality and cost-competitive coating products and engineering solutions to our clients worldwide.

Thin Intumescent Fireproof Coatings

Ultra-thin intumescent fireproof Coating is specially designed for steel structures and fire protection projects. The thin, lightweight Coating rapidly expands under high temperatures to form an insulating char layer, effectively extending structural fire resistance without adding significant weight.

Applications

Suitable for steel-structured buildings, industrial plants, public facilities, storage warehouses, bridges, and wind turbine towers for fire protection projects.

Services

We provide application guidance, technical support, sample testing, and customized Coating thickness to ensure successful project completion and compliance with fire resistance ratings.

Advantages

Extensive Experience: Years of experience in developing and producing fireproof Coatings

Advanced Technology: Complies with national and international fire protection standards, providing reliable protection

Rapid Expansion: Thin Coating that rapidly expands under high temperatures to form an insulating char layer

Lightweight Design: Does not add significant weight to steel structures, facilitating application

Customized Solutions: Formulations can be customized according to structural and fire resistance requirements

-

An Anti-Corrosive Primer is a specialized type of coating specifically formulated to protect metal surfaces from corrosion, rust, and other forms of degradation caused by exposure to moisture, oxygen,...

READ MORE -

Today, we have successfully developed an environmentally friendly and highly durable anti-corrosion paint for steel structures. This series of products integrates cutting-edge nanocomposite technology...

READ MORE -

In recent years, with the upgrading of consumption and the deepening of the country's "dual carbon" strategy, China's latex paint industry is undergoing a profound paradigm shift. The focus of industr...

READ MORE -

With the in-depth advancement of the national "dual carbon" strategy and the continuous improvement of building quality requirements, the polymer cement (JS) waterproof coating industry, which is a co...

READ MORE -

Today, Zhejiang Bolei Industrial Group Co., LTD., which enjoys a high reputation in the field of building safety and protection, grandly announced the launch of its newly developed high-performance fi...

READ MORE

Main Classifications of Thin Intumescent Fireproof Coatings

Depending on the environmental requirements and specific application scenarios of a construction project, Zhejiang Bolei Coatings Co., Ltd. provides three primary categories of Thin Intumescent Fireproof Coatings. Each category is formulated through precision chemical engineering to address specific structural challenges and atmospheric conditions. The effectiveness of these Thin Intumescent Fireproof Coatings lies in a balanced chemical synergy. At Zhejiang Bolei Coatings Co., Ltd., our chemists focus on the Intumescent Trinity: the acid source, the carbon source, and the blowing agent. When heat is applied, the acid source decomposes to release a strong acid which reacts with the carbon source to form a thick carbonaceous char, while the blowing agent releases inert gases that expand the char into a highly effective thermal barrier.

Water-based Thin Intumescent Fireproof Coatings

- Characteristics: These coatings utilize water as the primary solvent. They are characterized by extremely low VOC (Volatile Organic Compound) content and a lack of pungent chemical odors.

- Advantages: As a flagship eco-friendly solution from Zhejiang Bolei Coatings Co., Ltd., these coatings are ideal for projects where sustainability is a priority. Zhejiang Bolei Coatings Co., Ltd. is at the forefront of developing next-generation water-based Thin Intumescent Fireproof Coatings, investing in bio-based carbon sources and halogen-free flame retardants to reduce environmental footprints.

- Key Scenarios: Schools, hospitals, and residential interiors. Our water-based range is constantly being improved to offer the same durability as solvent-based systems, ensuring environmental responsibility.

Solvent-based Thin Intumescent Fireproof Coatings

- Characteristics: Formulated with organic solvents, these coatings offer superior weather resistance and moisture immunity compared to water-based alternatives.

- Advantages: They feature a faster drying time and exhibit higher stability when applied in low-temperature or high-humidity environments. This makes them the reliable choice for challenging construction schedules.

- Key Scenarios: Semi-exposed structures and unsealed industrial plants. Zhejiang Bolei Coatings Co., Ltd. subjects these solvent-based Thin Intumescent Fireproof Coatings to rigorous environmental stress tests, including accelerated weathering and moisture cycles.

Epoxy-based Thin Intumescent Fireproof Coatings

- Characteristics: Based on a high-performance two-component epoxy resin system, these coatings provide an exceptionally hard finish.

- Advantages: In addition to advanced fire protection, they offer extreme anti-corrosion properties and resistance to mechanical impact. Our research into epoxy-based Thin Intumescent Fireproof Coatings has pushed the boundaries of what thin coatings can achieve in hydrocarbon fire scenarios.

- Key Scenarios: Petrochemical refineries and offshore oil platforms. For these versions, salt spray testing is conducted by Zhejiang Bolei Coatings Co., Ltd. to simulate coastal environments, ensuring steel integrity is not compromised over decades.

Classification Performance Parameter Reference Table

The following data represents the typical performance metrics of the three types of Thin Intumescent Fireproof Coatings produced by Zhejiang Bolei Coatings Co., Ltd.:

| Feature | Water-based | Solvent-based | Epoxy-based |

|---|---|---|---|

| Environmental Grade | Excellent (Low VOC) | Standard | Formula Dependent |

| Drying Time (Surface) | 2 - 4 Hours | 1 - 2 Hours | 4 - 8 Hours |

| Moisture Resistance | Moderate (Requires Topcoat) | Good | Excellent |

| Recommended Use | Standard Interior | General Interior/Exterior | Industrial/Marine |

Construction Technology and Technical Requirements

To ensure that Thin Intumescent Fireproof Coatings perform as intended during a fire event, standardized application procedures are mandatory. Zhejiang Bolei Coatings Co., Ltd. does not merely supply high-quality coating products; we provide comprehensive engineering guidance and thickness calculations based on specific structural loads and fire duration requirements. As a subsidiary of Bolei Industrial Group, Zhejiang Bolei Coatings Co., Ltd. benefits from a stable raw material supply chain, ensuring every batch of Thin Intumescent Fireproof Coatings meets exact chemical compositions for safety certification.

Core Construction Steps

Substrate Surface Preparation: Steel surfaces must undergo thorough rust removal, typically requiring a cleanliness level of Sa 2.5 or higher. Removing oil, scale, and moisture is the fundamental step in guaranteeing the long-term adhesion of Thin Intumescent Fireproof Coatings.

Primer Compatibility (Primer Coat): A compatible anti-corrosion primer must be applied before the fireproof layer. Zhejiang Bolei Coatings Co., Ltd. recommends high-performance epoxy zinc-rich primers to prevent rust from compromising the stability of the fireproof layer.

Layered Spraying Application: Thin Intumescent Fireproof Coatings are generally applied using airless spray technology for maximum efficiency and smoothness. However, Zhejiang Bolei Coatings Co., Ltd. also provides formulations suitable for brush and roller application, which are essential for smaller touch-up jobs, complex joints, or areas where overspray must be strictly avoided.

Environmental Monitoring: The ambient temperature during construction should be maintained between 5 and 38 degrees Celsius, with relative humidity below 85 percent. Zhejiang Bolei Coatings Co., Ltd. ensures that the rheology of our Thin Intumescent Fireproof Coatings is specifically engineered to prevent sagging on vertical surfaces.

Recommended Construction Parameters for Thin Intumescent Fireproof Coatings

Based on decades of engineering experience, Zhejiang Bolei Coatings Co., Ltd. recommends the following technical parameters:

| Parameter | Technical Standard / Requirement |

|---|---|

| Application Tool | Airless sprayer with a pressure ratio of 45:1 or higher |

| Nozzle Diameter | 0.019 inch - 0.025 inch (0.48mm - 0.64mm) |

| Thinner Addition | Model dependent, typically not exceeding 5 percent |

| Single Layer Dry Film Thickness (DFT) | 300 micrometers - 500 micrometers (depending on fire rating) |

| Recoat Interval | 24 Hours (at 23 degrees Celsius with good ventilation) |

| Topcoat Compatibility | Apply only after the fireproof coating is fully cured |

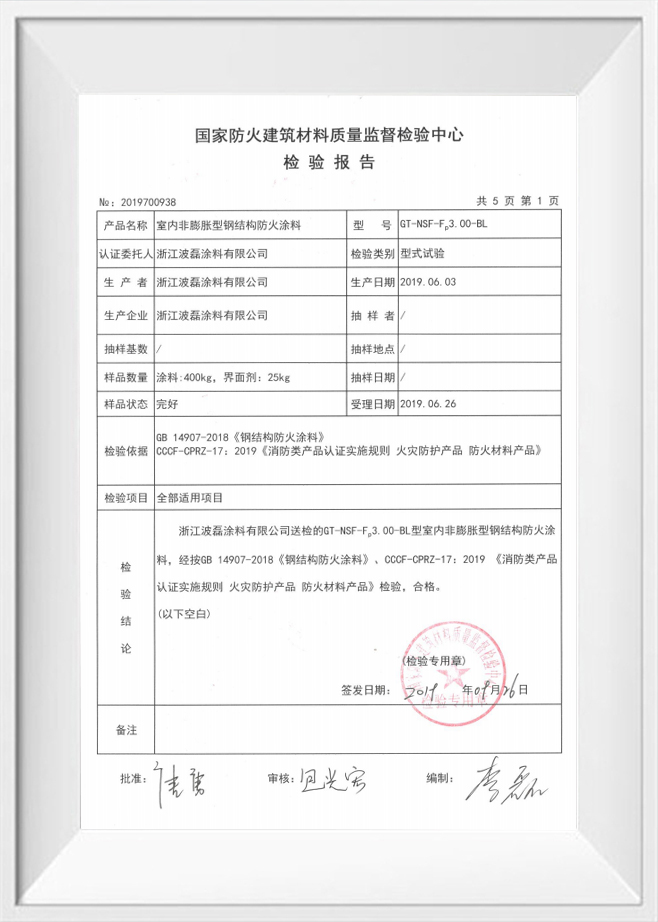

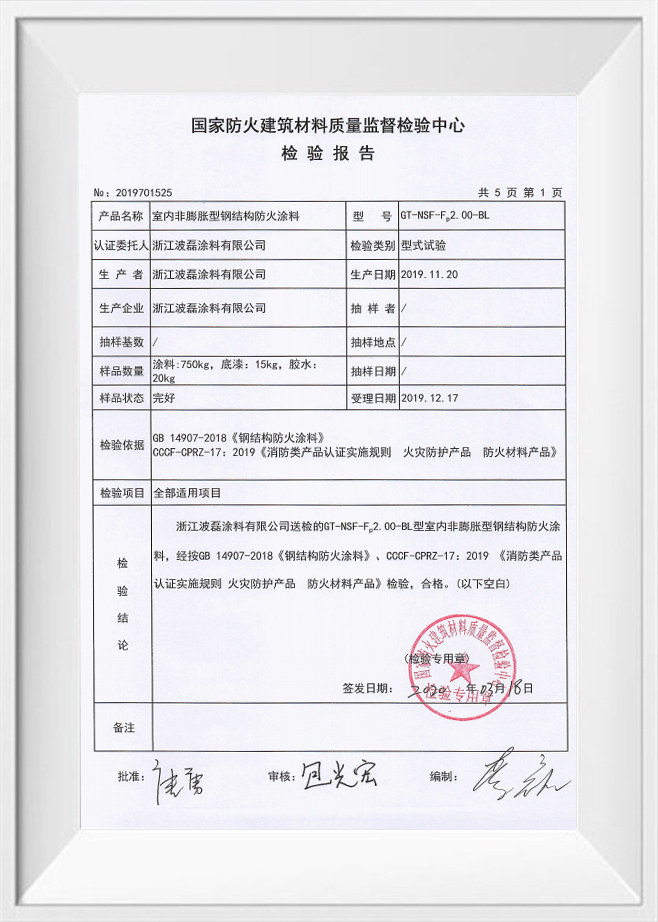

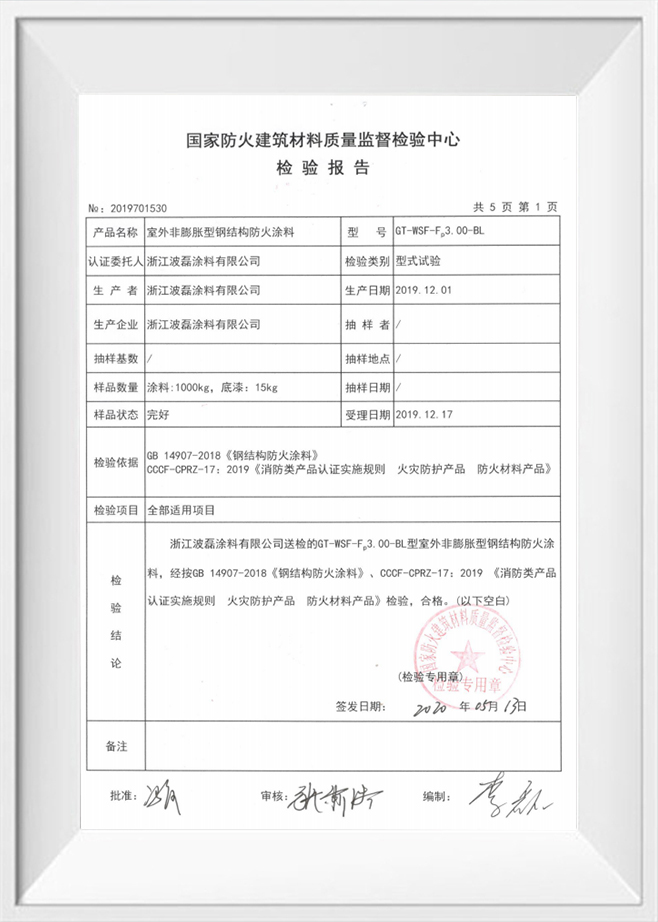

Performance Evaluation and Certification Standards

The quality of Thin Intumescent Fireproof Coatings is measured by their performance in standardized fire simulation tests. The R&D team at Zhejiang Bolei Coatings Co., Ltd. strictly follows global standards, including ASTM, BS, and EN protocols. Each batch of Thin Intumescent Fireproof Coatings undergoes thermal analysis to confirm its expansion characteristics before leaving our factory, ensuring the product maintains steel temperatures below the critical failure point (500 to 550 degrees Celsius) for extended periods.

Relationship Between Fire Rating and Coating Thickness

The Fire Resistance Level (FRL) is determined based on the steel member's Hp/A ratio and the thickness of the Thin Intumescent Fireproof Coatings. The table below shows typical thickness reference values provided by Zhejiang Bolei Coatings Co., Ltd.:

| Fire Rating | Typical Dry Film Thickness (DFT) | Application Examples |

|---|---|---|

| 0.5 Hour (30 min) | 0.50mm - 0.80mm | Secondary beams, light steel structures |

| 1.0 Hour (60 min) | 1.00mm - 1.50mm | Commercial building main beams |

| 1.5 Hour (90 min) | 1.80mm - 2.50mm | High-rise structural frameworks |

| 2.0 Hour (120 min) | 2.80mm - 3.50mm | Critical load-bearing columns |

Key Performance Indicators

Beyond fire timing, Thin Intumescent Fireproof Coatings produced by Zhejiang Bolei Coatings Co., Ltd. must pass several critical tests:

- Bonding Strength: Ensuring the coating does not peel off during the thermal expansion caused by high fire temperatures.

- Water/Freeze-Thaw Resistance: Guaranteeing that the coating performance does not degrade over years of service in varying climates.

- Expansion Ratio: Under standard temperature curves, the foaming ratio must reach a stable range, transforming a millimeter-thin film into an insulating shield several centimeters thick.

Application Advantages of Thin Intumescent Fireproof Coatings

Choosing Thin Intumescent Fireproof Coatings from Zhejiang Bolei Coatings Co., Ltd. provides significant economic and engineering benefits. These coatings are vital in modern designs involving large, open-span steel structures. Unlike traditional fireproofing which hides the steel under bulky layers of mineral wool, our coatings allow the structural integrity of the building to be visible. By choosing Zhejiang Bolei Coatings Co., Ltd., architects can achieve both safety and beauty for high-traffic railway stations or sophisticated art galleries.

Superior Aesthetics: The thin and smooth finish perfectly preserves the geometric beauty of modern steel structures. It is the preferred choice for airports and museums where the structural steel is a visible design element.

Space Optimization: The minimal thickness of the coating occupies almost no extra space, increasing the internal clear height and usable floor area of the building.

Load Reduction: The extremely light weight significantly reduces the dead load on the building structure, which helps optimize foundation design and reduce overall construction costs.

Ease of Maintenance: The coatings are durable and robust. Zhejiang Bolei Coatings Co., Ltd. provides detailed maintenance manuals for its Thin Intumescent Fireproof Coatings to help identify physical damage or chemical contamination that could hinder expansion.

FAQ

Q1: What is the service life of Thin Intumescent Fireproof Coatings?

In indoor, dry, and well-ventilated environments, the design service life of high-quality Thin Intumescent Fireproof Coatings is typically 10 to 15 years or more. Zhejiang Bolei Coatings Co., Ltd. recommends periodic inspections of critical areas to ensure the Thin Intumescent Fireproof Coatings remain intact and functional.

Q2: Is a thicker coating always better for fire performance?

While increasing thickness can extend fire protection time within a certain range, every Thin Intumescent Fireproof Coating has a performance saturation point. If a single application is too thick, it can lead to uneven internal stress. Construction must strictly follow the technical specifications provided by Zhejiang Bolei Coatings Co., Ltd. to ensure industrial reliability.

Q3: Why is it necessary to use specific primers and topcoats?

Thin Intumescent Fireproof Coatings act as a system. The primer prevents corrosion and provides adhesion; the topcoat provides decoration and protects the fireproof layer from UV rays and moisture. Zhejiang Bolei Coatings Co., Ltd. provides complete integrated solutions where all layers work in synergy during a fire event.

Q4: What are the differences between Water-based and Solvent-based Thin Intumescent Fireproof Coatings?

| Performance Metric | Water-based | Solvent-based |

|---|---|---|

| VOC Content | less than or equal to 50 g/L | less than or equal to 400 g/L |

| Minimum Construction Temp | 10 degrees Celsius | minus 5 degrees Celsius |

| Water Resistance Test | 24h No Blistering | 72h+ No Abnormality |

| Surface Drying Time | 2 - 4 Hours | 0.5 - 1.5 Hours |

| Recommended Storage | 5 to 35 degrees Celsius | 0 to 40 degrees Celsius |

Q5: How does high humidity affect the construction of Thin Intumescent Fireproof Coatings?

High humidity (RH greater than 85 percent) slows the evaporation of solvents or water in Thin Intumescent Fireproof Coatings, leading to soft films or sagging. Zhejiang Bolei Coatings Co., Ltd. reminds contractors to use dehumidifiers when working in rainy seasons. Our international trade department ensures that our Thin Intumescent Fireproof Coatings reach construction sites globally with all necessary documentation and technical support for various climates.

English

English

ENG

ENG

English

English