Anti-Corrosive Primer and Its Core Role in Industrial Protection

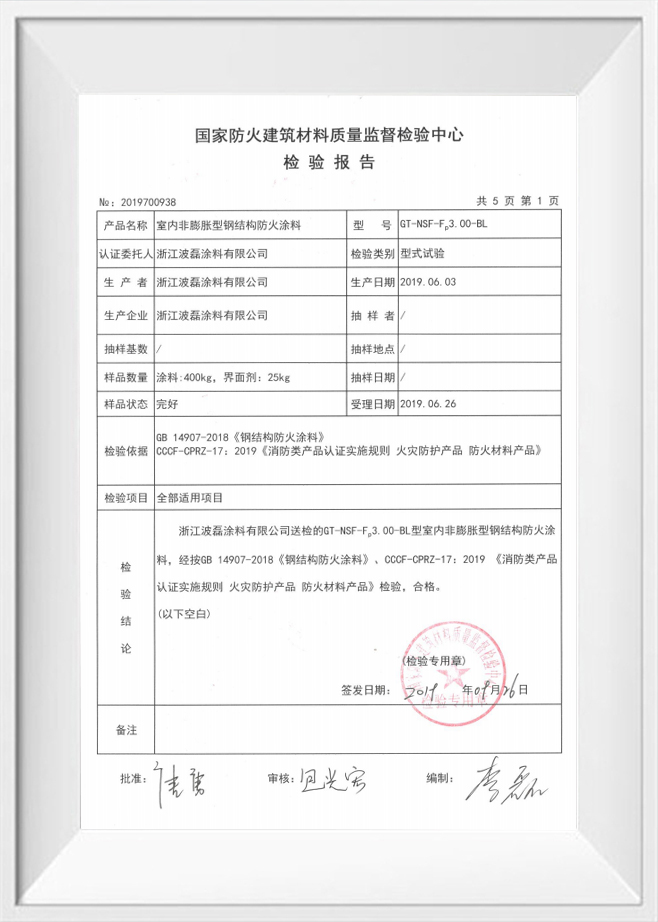

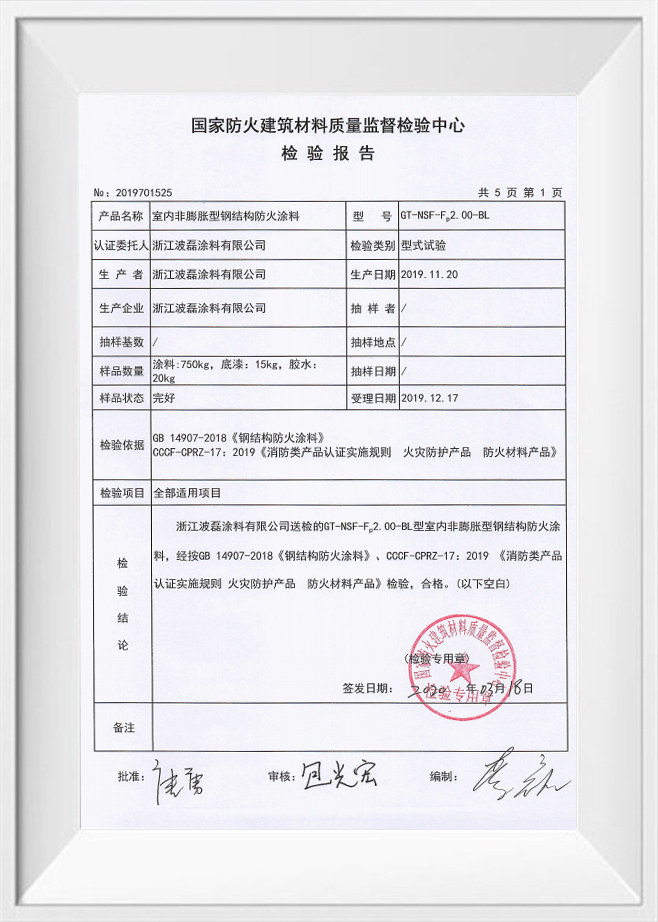

In the field of metal protection, Anti-Corrosive Primer is more than just a simple base coat; it is the lifeline of the entire coating system. As a core product within the R&D system of Zhejiang Bolei Coatings Co., Ltd., our Anti-Corrosive Primer is designed to provide long-term barrier protection and chemical inhibition for metal substrates, preventing structural damage caused by environmental oxidation.

Definition and Basic Functions of Anti-Corrosive Primer

Anti-Corrosive Primer is the first layer of coating applied directly to a treated metal surface. Its primary task is to establish a solid barrier that prevents oxygen, moisture, and corrosive ions from penetrating the metal surface. The primer series produced by Zhejiang Bolei Coatings Co., Ltd. utilizes precise formulas to ensure excellent chemical stability even in extreme industrial environments.

Core Protection Mechanisms

Physical Barrier Effect: Anti-Corrosive Primer forms a dense film that physically isolates external corrosive media.

Chemical Passivation and Inhibition: Anti-rust pigments in the primer (such as zinc phosphate) react with the metal surface to form a passivation film, blocking corrosion at the microscopic level.

Enhanced Interface Adhesion: Zhejiang Bolei Coatings Co., Ltd. has optimized the molecular structure of its Anti-Corrosive Primer to ensure it tightly grips the metal substrate and provides an ideal surface for subsequent topcoats, preventing peeling.

Comparison of Common Anti-Corrosive Primer Performance Parameters

To help you select the most suitable Anti-Corrosive Primer for specific working conditions, we have compared several mainstream primers under Zhejiang Bolei Coatings Co., Ltd.:

| Performance Metric |

Epoxy Anti-Corrosive Primer |

Zinc-Rich Anti-Corrosive Primer |

Alkyd Anti-Corrosive Primer |

Waterborne Anti-Corrosive Primer |

| Main Mechanism |

Barrier and Adhesion |

Cathodic Protection |

Physical Barrier |

Barrier (Eco-friendly) |

| Chemical Resistance |

Excellent |

Strong |

General |

Moderate |

| Adhesion (Cross-cut) |

Grade 0 - 1 |

Grade 1 |

Grade 1 - 2 |

Grade 1 |

| Recommended DFT |

40 - 60 microns |

60 - 80 microns |

30 - 45 microns |

40 - 55 microns |

| Thinner Type |

Special Organic Solvent |

Special Organic Solvent |

Solvent Oil / Xylene |

Deionized Water |

| Application Environment |

Highly Corrosive Industrial |

Offshore / Heavy Steel |

Indoor / Light Industrial |

Eco-sensitive Projects |

Why Choose Solutions from Zhejiang Bolei Coatings Co., Ltd.

As a core member of Bolei Industrial Group, Zhejiang Bolei Coatings Co., Ltd. relies on a stable raw material supply chain and a strict quality control system to ensure every bucket of Anti-Corrosive Primer meets international industrial standards. Our primer products are not only cost-competitive but also offer customized formula adjustments for different regional climatic characteristics.

Common Types of Anti-Corrosive Primer and Their Characteristics

In the industrial protection system, the choice of Anti-Corrosive Primer is crucial for different environmental challenges and substrate characteristics. Zhejiang Bolei Coatings Co., Ltd. has developed a series of highly targeted products to meet the strict long-term anti-corrosion requirements of global clients.

Epoxy Anti-Corrosive Primer

As a star product of Zhejiang Bolei Coatings Co., Ltd., epoxy primers are known for their excellent adhesion and chemical resistance. This Anti-Corrosive Primer features two-component curing, resulting in a tough film with excellent resistance to water, oil, acids, and alkalis. It is widely used in chemical plants, sewage treatment facilities, underground pipe networks, and heavy machinery.

Zinc-Rich Anti-Corrosive Primer

This Anti-Corrosive Primer contains a high proportion of zinc powder, providing sacrificial anodic cathodic protection for steel structures. Even if the film is locally scratched, the zinc powder oxidizes before the steel, preventing the spread of rust. Zhejiang Bolei Coatings Co., Ltd. recommends this primer for bridges, offshore engineering, and large steel frames.

Alkyd Anti-Corrosive Primer

An economical and efficient single-component Anti-Corrosive Primer. It is easy to apply, fast drying, and has lower requirements for surface preparation. It is suitable for light industrial equipment and civil metal facilities in general atmospheric environments.

Waterborne Anti-Corrosive Primer

In line with global environmental trends, Zhejiang Bolei Coatings Co., Ltd. has developed a high-performance waterborne series. It uses water as a thinner, featuring low VOC, no irritating odor, and high fire resistance rating. It is suitable for indoor confined space construction or projects with strict environmental requirements.

Detailed Technical Parameter Comparison Table

| Key Parameter |

Epoxy Primer |

Zinc-Rich Primer |

Alkyd Primer |

Waterborne Primer |

| Solid Content (%) |

75 plus or minus 2 |

85 plus or minus 3 |

60 plus or minus 2 |

55 plus or minus 5 |

| Mixing Ratio |

4:1 or 5:1 |

3:1 |

Single Component |

Single or Double |

| Surface Dry (25C) |

Less than 2 hours |

Less than 1 hour |

Less than 0.5 hours |

Less than 1 hour |

| Full Dry (25C) |

24 hours |

24 hours |

12 hours |

24 hours |

| Theoretical Coverage |

6.0 - 8.0 m2/kg |

3.0 - 5.0 m2/kg |

8.0 - 10.0 m2/kg |

7.0 - 9.0 m2/kg |

| Salt Spray Resistance |

Over 1000 hours |

Over 1500 hours |

Over 200 hours |

Over 500 hours |

How to Select Anti-Corrosive Primer for Different Metal Substrates

The diversity of metal materials dictates that anti-corrosion solutions cannot be "one size fits all." Zhejiang Bolei Coatings Co., Ltd. has found that the physical and chemical properties of the substrate directly affect the adhesion and stability of the Anti-Corrosive Primer.

Anti-Corrosive Primer Selection for Ferrous Metals (Steel)

Steel is the material most susceptible to oxidation. For carbon steel or cast iron, Zhejiang Bolei Coatings Co., Ltd. recommends primers containing active anti-rust pigments. For general steel structures, epoxy zinc-rich or zinc phosphate Anti-Corrosive Primer is suggested for dual protection via electrochemical and barrier effects. For rusted surfaces where sandblasting is impossible, our penetrative Anti-Corrosive Primer can stabilize residual rust layers.

Anti-Corrosive Primer Selection for Non-Ferrous Metals (Aluminum, Galvanized Steel)

Aluminum and galvanized layers have dense, smooth surfaces where traditional primers struggle to bond. Zhejiang Bolei Coatings Co., Ltd. has developed wash primers (etch primers) or specialized two-component epoxy primers that create a molecular-level bond. This Anti-Corrosive Primer avoids saponification-induced failure, which often occurs with traditional alkyd paints on galvanized surfaces.

Substrate and Anti-Corrosive Primer Compatibility Table

| Substrate Type |

Recommended Primer |

Adhesion Mechanism |

Key Performance |

| Carbon Steel |

Zinc-Rich Epoxy |

Cathodic and Barrier |

Zinc content 70% - 85% |

| Stainless Steel |

High-Bond Epoxy |

Intermolecular force |

Grade 0 Adhesion |

| Aluminum Alloy |

Wash Primer |

Chemical Etching |

Coverage 12 - 14 m2/L |

| Galvanized (HDG) |

Waterborne/Epoxy |

Polar group adsorption |

Salt spray over 800h |

Key Steps and Process Standards for Applying Anti-Corrosive Primer

Even the highest quality Anti-Corrosive Primer requires strict application processes. The engineering team at Zhejiang Bolei Coatings Co., Ltd. has summarized a standardized workflow.

Surface Pretreatment: The Foundation of Primer Performance

Zhejiang Bolei Coatings Co., Ltd. emphasizes that over 70% of coating failures are caused by improper surface treatment. This involves degreasing with specialized cleaners to remove oils. For heavy-duty Anti-Corrosive Primer, the rust removal should reach Sa 2.5 or St 3 level. Ideal roughness (40 - 75 microns) significantly increases the physical bonding area.

Coating Preparation and Mixing

For two-component Anti-Corrosive Primer produced by Zhejiang Bolei Coatings Co., Ltd., mixing accuracy is vital. Users must strictly follow the mass or volume ratio. After mixing, an induction time of 15 - 30 minutes is required. The pot life must be strictly observed, usually requiring the Anti-Corrosive Primer to be used within 4 - 6 hours.

Construction Environment Monitoring Indicators

| Parameter |

Recommended Range |

Impact on Anti-Corrosive Primer |

| Temperature |

5C - 35C |

Too low stops curing; too high causes pinholes |

| Relative Humidity |

Below 85% |

High humidity causes flash rust |

| Dew Point |

Steel Temp greater than DP plus 3C |

Prevents invisible condensation |

FAQ

Why can't I skip Anti-Corrosive Primer and apply the topcoat directly?

Topcoats provide UV resistance and aesthetics but lack chemical inhibition for the metal. The Anti-Corrosive Primer from Zhejiang Bolei Coatings Co., Ltd. contains active ingredients that passivate the metal. Without it, corrosion will spread horizontally beneath the film.

Can different types of Anti-Corrosive Primer be mixed or overlapped?

We do not recommend mixing different chemical systems. For example, the epoxy Anti-Corrosive Primer from Zhejiang Bolei Coatings Co., Ltd. has a different curing mechanism than alkyd primers. Always follow the compatibility chart provided by our technical team.

Re-coating Interval Comparison for Different Systems

| Comparison Item |

Epoxy Primer |

Zinc-Rich Primer |

Alkyd Primer |

| Compatible Topcoat |

Epoxy, PU, Fluorocarbon |

Epoxy MIO, PU |

Alkyd Topcoat only |

| Min. Interval |

4 - 6 hours |

2 - 4 hours |

8 - 12 hours |

| Max. Interval |

7 days (requires sanding) |

30 days |

No specific limit |

What are the risks of applying Anti-Corrosive Primer in humid or cold environments?

High humidity causes a water film on the metal, preventing the Anti-Corrosive Primer from bonding. For the two-component epoxy primers of Zhejiang Bolei Coatings Co., Ltd., temperatures below 5C will cause the curing reaction to stop, leading to a weak film structure.

English

English

ENG

ENG

English

English