In-Depth Analysis of the Core Functions of Anti-Corrosive Topcoat

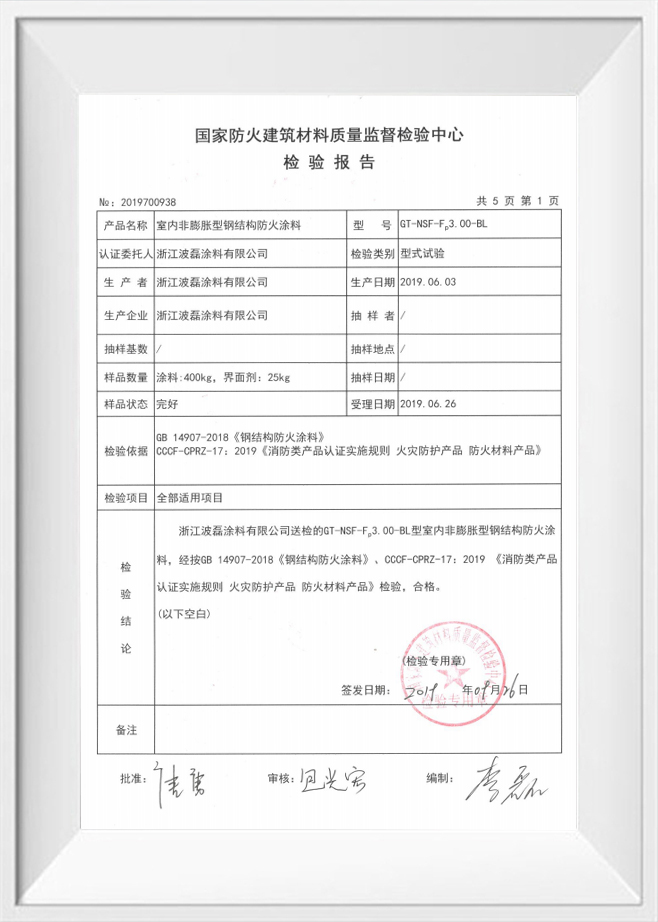

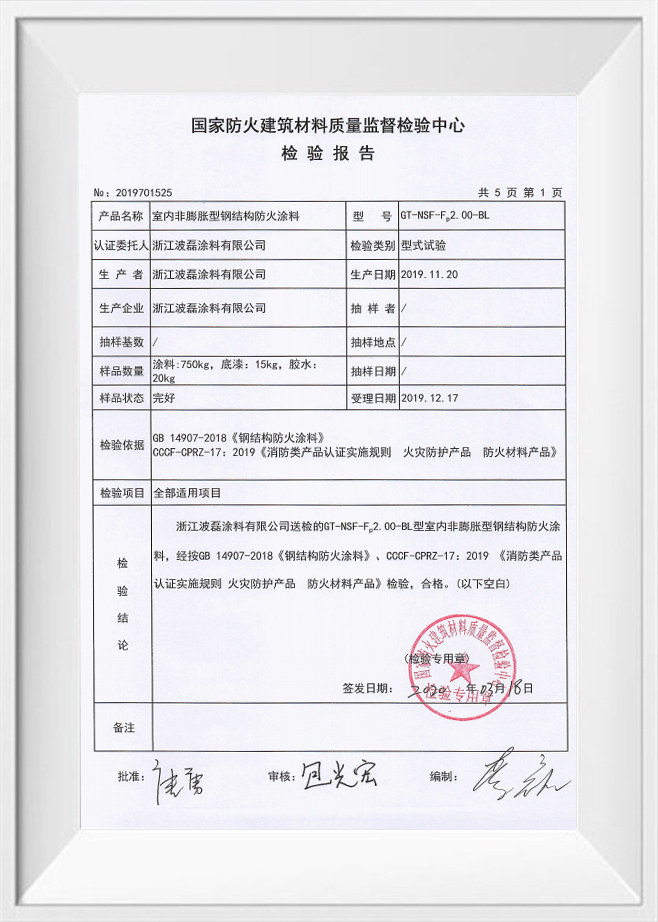

In the modern industrial protection system, an Anti-Corrosive Topcoat is far more than just a decorative layer; it is the final solid line of defense against environmental erosion. Zhejiang Bolei Coatings Co., Ltd., drawing on years of research and development in the field of corrosion protection, has endowed its Anti-Corrosive Topcoat products with exceptional physical and chemical shielding properties.

Core Functional Dimensions

Superior Shielding Effect: The Anti-Corrosive Topcoat manufactured by Zhejiang Bolei Coatings Co., Ltd. creates a dense molecular structure that effectively blocks water molecules, oxygen, and corrosive ions like chlorides from penetrating the substrate. This high density ensures that even in harsh chemical or marine atmospheric environments, the Anti-Corrosive Topcoat maintains the integrity of the coating system.

Weather Resistance and Protective Power: As the outermost layer, an Anti-Corrosive Topcoat must possess intense resistance to ultraviolet (UV) radiation. Our products prevent film chalking and embrittlement, thereby maintaining long-term mechanical strength and protecting the underlying primer from photo-degradation.

Decoration and Identification: Zhejiang Bolei Coatings Co., Ltd. focuses on the color and gloss retention of the Anti-Corrosive Topcoat, allowing it to maintain vivid color identification under long-term exposure to acid rain and salt spray, meeting the dual needs of industrial aesthetics and safety recognition.

Core Performance Parameter Comparison of Anti-Corrosive Topcoat

To assist clients in choosing the appropriate solution based on environmental severity, the following table lists typical Anti-Corrosive Topcoat performance data measured by the laboratories of Zhejiang Bolei Coatings Co., Ltd.:

| Performance Indicator |

Aliphatic Polyurethane Anti-Corrosive Topcoat |

Epoxy Anti-Corrosive Topcoat |

Fluorocarbon Anti-Corrosive Topcoat |

| UV Resistance |

Excellent |

Poor (Chalks easily) |

Superior (20+ years) |

| Salt Spray Resistance |

800h - 1200h |

1000h+ |

2500h+ |

| Adhesion (Grade) |

Grade 0 - 1 |

Grade 0 |

Grade 0 - 1 |

| Chemical Resistance |

Good |

Excellent |

Superior |

| Main Application |

Outdoor steel, machinery |

Indoor equipment, pipes |

Bridges, marine platforms |

Why Choose Zhejiang Bolei Coatings Co., Ltd.?

As a core subsidiary of the Bolei Industrial Group, Zhejiang Bolei Coatings Co., Ltd. possesses a complete raw material supply chain, ensuring every bucket of Anti-Corrosive Topcoat is produced using high-quality resins and weather-resistant pigments. Through a strict quality control system, we deliver not only coating products but also comprehensive engineering solutions.

Main Material Classifications of Anti-Corrosive Topcoat

The choice of material for the Anti-Corrosive Topcoat directly determines the service life of the entire anti-corrosion system. Zhejiang Bolei Coatings Co., Ltd. has developed and optimized four core material systems to ensure that every Anti-Corrosive Topcoat precisely matches client requirements across different global climates.

Core Material Analysis

Polyurethane (Aliphatic): This is the most widely used high-performance outdoor Anti-Corrosive Topcoat. Zhejiang Bolei Coatings Co., Ltd. utilizes pure aliphatic isocyanate curing agents to provide excellent gloss and color retention, along with a tough film and superior abrasion resistance.

Epoxy: Known for its unparalleled adhesion and chemical resistance. While it may chalk under UV exposure, as an Anti-Corrosive Topcoat for indoor steel structures, underground pipelines, or tank linings, its anti-corrosion efficacy is irreplaceable.

Fluorocarbon: Considered the "top-tier" choice for Anti-Corrosive Topcoat. The products manufactured by Zhejiang Bolei Coatings Co., Ltd. contain high-energy F-C bonds, capable of resisting extreme UV radiation and chemical erosion for over 20 years.

Acrylic: Suitable for lightweight anti-corrosion and scenarios requiring fast drying. This Anti-Corrosive Topcoat series offers quick drying times, easy application, and good economic value with basic weather resistance.

Technical Parameter Comparison Table

The following table provides a direct comparison of the physical parameters for different Anti-Corrosive Topcoat materials from Zhejiang Bolei Coatings Co., Ltd.:

| Technical Indicator |

Polyurethane (PU) |

Epoxy (EP) |

Fluorocarbon (FEVE) |

Acrylic (AC) |

| Solid Content |

65% +/- 3% |

75% +/- 5% |

60% +/- 2% |

50% +/- 5% |

| Surface Dry (25C) |

Less than 2 hours |

Less than 4 hours |

Less than 1 hour |

Less than 0.5 hour |

| Full Cure (25C) |

7 Days |

7 Days |

10 Days |

3 Days |

| QUV Resistance |

1000h (No blisters) |

200h (Chalking) |

4000h+ (High retention) |

600h |

| Mixing Ratio (W/W) |

5 to 1 |

4 to 1 |

10 to 1 |

Single component |

Application Process: Ensuring the Efficacy of Anti-Corrosive Topcoat

Professional application techniques are the key to unlocking the full protective potential of an Anti-Corrosive Topcoat. Zhejiang Bolei Coatings Co., Ltd. is committed to providing standardized technical support to ensure every layer of Anti-Corrosive Topcoat forms a perfect barrier.

Core Application Workflow and Key Control Points

Coating System Compatibility: An Anti-Corrosive Topcoat must be compatible with its primers and intermediate coats. Zhejiang Bolei Coatings Co., Ltd. recommends a "Primer-Intermediate-Topcoat" composite system. It is vital to ensure the overcoating interval between the Anti-Corrosive Topcoat and the underlying layers meets technical specifications to prevent adhesion failure.

Control of Dry Film Thickness (DFT): Achieving the designed thickness for the Anti-Corrosive Topcoat is critical. If the Anti-Corrosive Topcoat is too thin, the shielding effect is weakened; if it is too thick, it may lead to film cracking or solvent entrapment.

Environmental Restrictions: Dew point, humidity, and temperature play decisive roles. When applying Anti-Corrosive Topcoat from Zhejiang Bolei Coatings Co., Ltd., the substrate surface temperature should be at least 3C above the dew point, and relative humidity should be below 85%.

Application Parameters and Standards

The following are the reference standards set by Zhejiang Bolei Coatings Co., Ltd. for its Anti-Corrosive Topcoat products:

| Parameter |

Airless Spray |

Air Spray |

Brush/Roller |

| Thinner Ratio |

0 - 5% |

10 - 15% |

0 - 5% |

| Nozzle Pressure |

15 - 20 MPa |

0.3 - 0.5 MPa |

N/A |

| Single Layer DFT |

40 - 60 microns |

30 - 45 microns |

35 - 50 microns |

| Overcoating (25C) |

Min 6h |

Min 8h |

Min 12h |

Key Application Fields and Case Analysis

The actual effectiveness of an Anti-Corrosive Topcoat must be verified in complex service environments. Zhejiang Bolei Coatings Co., Ltd. has tailored solutions for core sectors worldwide.

Core Application Scenarios

Steel Structure Buildings: In urban and industrial plants, steel structures face long-term atmospheric oxidation. The polyurethane Anti-Corrosive Topcoat from Zhejiang Bolei Coatings Co., Ltd. provides excellent weather resistance, ensuring building exteriors do not fade for over 10 years.

Marine Engineering: In high-salt spray environments, the salt spray resistance of the Anti-Corrosive Topcoat is paramount. We recommend high-solid or fluorocarbon Anti-Corrosive Topcoat options to protect harbor cranes and offshore platforms from chloride ion penetration.

Petrochemical Equipment: Tank exteriors require chemical-resistant Anti-Corrosive Topcoat solutions. Our products resist hydrocarbon solvents and industrial gases, extending the maintenance cycles for Zhejiang Bolei Coatings Co., Ltd. clients.

Performance Requirements by Environment

| Requirement |

Urban Industrial (C3) |

Marine (C5-M) |

Heavy Chemical (C5-I) |

| Recommended Material |

Acrylic/Polyurethane |

Fluorocarbon |

Epoxy/Aliphatic PU |

| Salt Spray Test |

Greater than 480h |

Greater than 1440h |

Greater than 1200h |

| Topcoat DFT |

40 - 50 microns |

60 - 80 microns |

60 - 70 microns |

FAQ

Q: Why is it necessary to apply an Anti-Corrosive Topcoat if an anti-corrosion primer is already used?

A: Primers mainly provide electrochemical protection and adhesion, but lack UV resistance. The Anti-Corrosive Topcoat acts as the outermost "shield," preventing the primer from aging and failing due to sunlight and rain exposure.

Q: How can one determine if an Anti-Corrosive Topcoat has failed?

A: Observe the surface for loss of gloss, chalking, cracking, or rust spots. Zhejiang Bolei Coatings Co., Ltd. recommends routine testing every 3-5 years. If the Anti-Corrosive Topcoat loses integrity, moisture will cause corrosion.

Q: How does water-based Anti-Corrosive Topcoat compare to solvent-based versions?

A: High-performance water-based Anti-Corrosive Topcoat developed by Zhejiang Bolei Coatings Co., Ltd. matches solvent-based performance in standard industrial settings (C2-C3) while offering low VOC emissions.

Q: Does Zhejiang Bolei Coatings Co., Ltd. provide customized colors for Anti-Corrosive Topcoat?

A: Yes. As a professional manufacturer, we offer customization based on RAL and PANTONE standards, ensuring the Anti-Corrosive Topcoat aligns with the client's corporate visual identity.

English

English

ENG

ENG

English

English