What is Exterior Latex Paint and Its Core Advantages

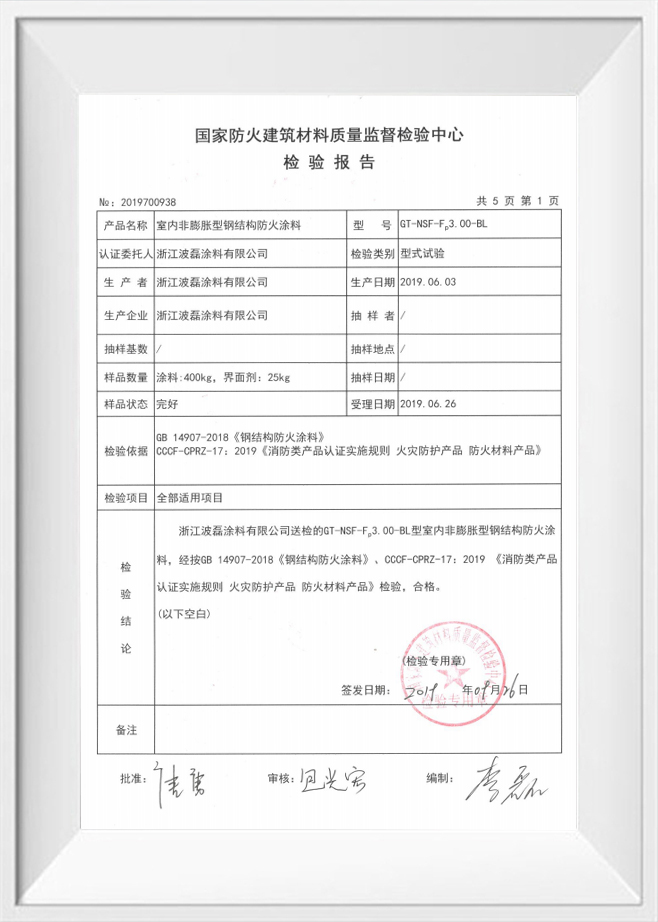

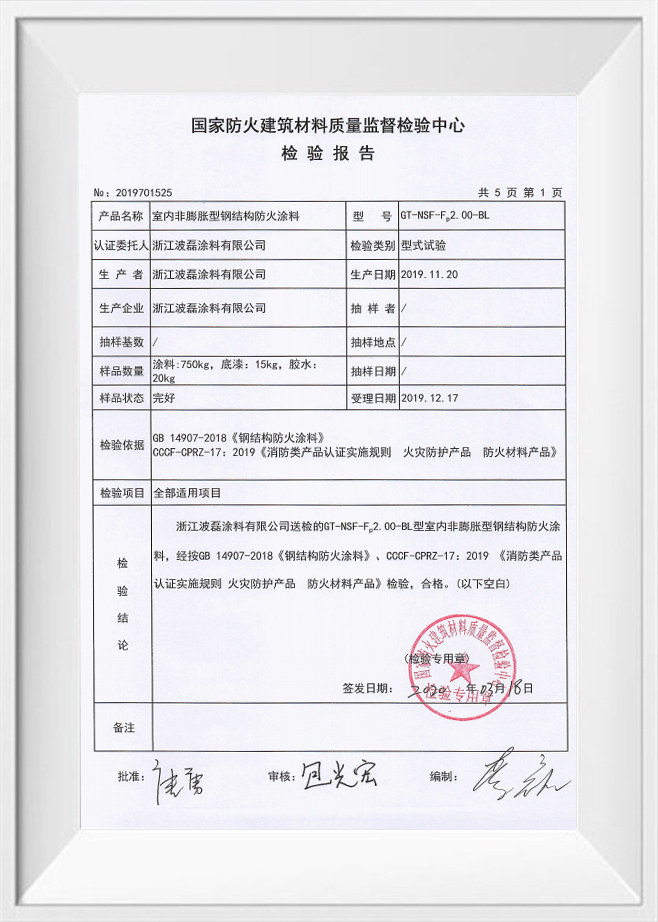

In the field of modern architectural coating, Exterior Latex Paint has established itself as the premier choice for protecting and beautifying building facades. As a flagship product line of Zhejiang Bolei Coatings Co., Ltd., our Exterior Latex Paint is engineered using high-performance emulsion technology to withstand the most demanding outdoor conditions. Zhejiang Bolei Coatings Co., Ltd. is a subsidiary of Bolei Industrial Group, with multiple subsidiaries engaged in coatings manufacturing, construction services, new material development, and international trade. Our Exterior Latex Paint reflects our commitment to delivering high-quality and cost-competitive engineering solutions to clients worldwide.

Definition and Chemical Composition

Exterior Latex Paint is a water-borne coating formulated with acrylic resins as the primary binder. Unlike solvent-based alternatives, the Exterior Latex Paint produced by Zhejiang Bolei Coatings Co., Ltd. utilizes water as the carrier, which evaporates during the curing process. This significantly minimizes the release of Volatile Organic Compounds (VOCs), making our Exterior Latex Paint an environmentally responsible choice for large-scale construction. The molecular structure of our Exterior Latex Paint is designed to create a cohesive, tough barrier that adheres deeply to various substrates.

Superior Flexibility and Thermal Expansion

Exterior surfaces are constantly subjected to thermal stress, causing substrates like concrete and masonry to expand and contract. High-quality Exterior Latex Paint must possess exceptional elasticity. The R&D team at Zhejiang Bolei Coatings Co., Ltd. has optimized the polymer backbone of our Exterior Latex Paint to ensure it functions like a flexible "skin." This allows the Exterior Latex Paint to move in sync with the building, effectively preventing the microscopic cracks that lead to catastrophic peeling and water infiltration. This durability is a hallmark of the Exterior Latex Paint manufactured in our advanced facilities.

One-way Breathability and Moisture Management

One of the most critical features of professional-grade Exterior Latex Paint is its "breathability" or vapor permeability. Zhejiang Bolei Coatings Co., Ltd. ensures that its Exterior Latex Paint provides a sophisticated microporous structure. This allows internal moisture trapped within the wall to escape as vapor, while preventing liquid rainwater from penetrating the surface. Without this feature, Exterior Latex Paint would likely suffer from hydrostatic pressure, leading to unsightly blisters and the degradation of the underlying structure.

Weather Resistance and UV Stability

Ultraviolet radiation is the primary cause of coating degradation. The Exterior Latex Paint produced by Zhejiang Bolei Coatings Co., Ltd. incorporates high-stability pigments and UV absorbers. This ensures that the Exterior Latex Paint maintains its color integrity and structural bond even under intense solar exposure. Compared to traditional coatings, our Exterior Latex Paint exhibits significantly lower rates of chalking and erosion, providing a long-lasting aesthetic finish that reduces long-term maintenance costs for our global partners.

Parameter Comparison: Exterior Latex Paint vs. Traditional Oil-based Exterior Paint

| Performance Metric |

Exterior Latex Paint (Acrylic System) |

Traditional Oil-based Paint (Alkyd System) |

| Flexibility |

Excellent: Maintains elasticity over years |

Poor: Becomes brittle and prone to cracking |

| Drying Time |

Fast: Touch-dry in 1-2 hours |

Slow: Requires 12-24 hours to cure |

| Eco-friendliness |

High: Low VOC and water-cleanable |

Low: High VOC and requires chemical solvents |

| Vapor Permeability |

Superior: Allows walls to "breathe" |

Very Low: Traps moisture, causing rot/blisters |

| UV Resistance |

Extremely High: Resists fading and chalking |

Moderate: Tends to yellow and oxidize quickly |

| Cleanup |

Simple: Requires only soap and water |

Laborious: Requires mineral spirits or thinners |

Key Considerations for Selecting Exterior Latex Paint

Choosing the appropriate Exterior Latex Paint requires a technical understanding of the environment and the desired finish. Zhejiang Bolei Coatings Co., Ltd. advises that customers evaluate Exterior Latex Paint based on sheen, biological resistance, and resin purity. As a professional paint manufacturer based in China, we ensure that our Exterior Latex Paint formulations are adjusted to meet the specific climatic challenges of different regions, from tropical humidity to arid heat.

Scientific Choice of Sheen Levels

The gloss level of Exterior Latex Paint impacts both the visual result and the physical durability of the coating. Zhejiang Bolei Coatings Co., Ltd. offers several standard sheen levels for our Exterior Latex Paint:

Flat/Matte: This version of Exterior Latex Paint is ideal for hiding surface imperfections on uneven masonry. It provides a non-reflective, elegant finish often used on historic restorations or large industrial facades.

Satin/Eggshell: The most versatile Exterior Latex Paint sheen. It offers a slight luster and significantly better washability than matte finishes, making it the preferred choice for residential exterior walls.

Semi-Gloss/Gloss: High-sheen Exterior Latex Paint creates a very hard, smooth film. It is exceptionally resistant to dirt pickup and is primarily used for trim, doors, and shutters. Zhejiang Bolei Coatings Co., Ltd. utilizes specialized resins in these paints to ensure they do not become "tacky" in high temperatures.

Mildew and Algae Resistance

In damp climates, microbial growth can destroy the appearance and integrity of a wall. Zhejiang Bolei Coatings Co., Ltd. fortifies its Exterior Latex Paint with advanced, environmentally safe biocides. These additives ensure that the Exterior Latex Paint film remains hostile to spores, preventing the dark staining associated with mold and algae. This is particularly vital for Exterior Latex Paint applied in shaded areas or regions with high annual rainfall.

Resin Composition: 100% Acrylic vs. Vinyl Acetate

The durability of Exterior Latex Paint is directly proportional to its resin quality. Zhejiang Bolei Coatings Co., Ltd. specializes in 100% pure acrylic Exterior Latex Paint. Unlike cheaper "vinyl-acrylic" blends, our 100% acrylic Exterior Latex Paint offers superior adhesion to difficult surfaces, better resistance to alkaline masonry, and significantly longer lifespans. Investing in high-resin-count Exterior Latex Paint ensures a lower total cost of ownership over the building's lifecycle.

Parameter Comparison: Performance of Different Exterior Latex Paint Resins

| Feature |

100% Acrylic Exterior Latex Paint |

Vinyl-Modified Exterior Latex Paint |

| Adhesion Strength |

Maximum: Bonds to wood, masonry, and metal |

Moderate: May fail on smooth or chalky surfaces |

| Alkali Resistance |

High: Safe for use on "hot" new concrete |

Low: Resin can break down on alkaline surfaces |

| Film Integrity |

Outstanding: Remains flexible for over a decade |

Fair: Prone to cracking after 3-5 years |

| Wet Scrub Resistance |

Excellent: Can withstand repeated cleaning |

Average: Film may erode during scrubbing |

| Long-term Value |

Highest: Extended repainting intervals |

Lower: Requires frequent maintenance cycles |

Surface Preparation Before Using Exterior Latex Paint

The success of an Exterior Latex Paint application is 70% preparation and 30% application. Zhejiang Bolei Coatings Co., Ltd. provides comprehensive technical support to ensure that the substrate is properly conditioned to receive the Exterior Latex Paint. Our engineering solutions emphasize that a clean, dry, and stable surface is the only way to guarantee the performance of our Exterior Latex Paint.

Cleaning and Bio-decontamination

Dust, salt, and oils act as bond-breakers for Exterior Latex Paint. Zhejiang Bolei Coatings Co., Ltd. recommends high-pressure water blasting to remove surface contaminants. For surfaces with existing biological growth, a specialized wash must be applied before the Exterior Latex Paint. Ensuring the substrate is sterile prevents spores from proliferating beneath the Exterior Latex Paint film, which could lead to premature delamination.

Repair of Existing Coatings

If applying Exterior Latex Paint over an existing finish, any loose or failing material must be mechanically removed. Zhejiang Bolei Coatings Co., Ltd. advises that all edges be feathered by sanding to ensure a seamless transition. The integrity of the new Exterior Latex Paint is only as strong as the layer beneath it. Cracks should be filled with high-quality elastomeric fillers that are compatible with Exterior Latex Paint systems.

The Strategic Use of Primer

Primers are essential for specific substrates when using Exterior Latex Paint. New masonry requires an alkali-resistant sealer to protect the Exterior Latex Paint from "saponification" (a chemical breakdown). Highly porous surfaces should be primed to prevent the Exterior Latex Paint from being absorbed too quickly, which results in a patchy finish. Zhejiang Bolei Coatings Co., Ltd. produces a range of primers specifically designed to provide a perfect mechanical bond for our Exterior Latex Paint.

Environmental Controls During Construction

The curing of Exterior Latex Paint is a delicate chemical process. Zhejiang Bolei Coatings Co., Ltd. insists that contractors monitor local weather conditions. If the Exterior Latex Paint dries too quickly in direct sun or fails to dry due to high humidity, the film will not achieve its maximum density. Proper timing ensures the Exterior Latex Paint forms a cohesive, protective shield.

Environmental Parameter Reference Table: Ideal Conditions for Exterior Latex Paint

| Environmental Metric |

Ideal Range |

Technical Impact |

| Air Temperature |

10°C - 29°C |

Ensures proper coalescence of Exterior Latex Paint molecules |

| Relative Humidity |

40% - 70% |

Allows for a controlled evaporation rate of the water carrier |

| Substrate Moisture |

Below 10% |

Prevents moisture from being trapped under the Exterior Latex Paint |

| Application Time |

10 AM - 3 PM |

Avoids the dew point and extreme evening temperature drops |

| Rain Forecast |

No rain for 12 hours |

Prevents the wet Exterior Latex Paint from washing off the wall |

Application Techniques and Tools for Exterior Latex Paint

A professional finish requires a marriage of high-quality Exterior Latex Paint and refined application techniques. Zhejiang Bolei Coatings Co., Ltd. supports industrial and construction sectors with technical guidance on the most efficient ways to apply Exterior Latex Paint. Our products are formulated for excellent workability across various tool sets.

Precision Tool Selection

The choice of application method affects both the thickness and the uniformity of the Exterior Latex Paint:

Airless Spraying: This is the most efficient method for large-scale industrial projects. Zhejiang Bolei Coatings Co., Ltd. manufactures Exterior Latex Paint with precise viscosity to ensure it atomizes perfectly, providing a uniform film even on complex architectural shapes.

Rolling: Best for textured masonry and residential walls. Using a heavy-nap roller with our Exterior Latex Paint allows for a thicker "build," providing superior protection and coverage in fewer passes.

Brushing: Essential for detail work and "cutting in." Our Exterior Latex Paint is designed with excellent "leveling" properties, meaning brush marks tend to disappear as the paint cures, leaving a smooth surface.

The Importance of "Wet Edge"

To avoid visible lap marks, it is crucial to maintain a "wet edge" during the application of Exterior Latex Paint. This means never allowing a section of Exterior Latex Paint to dry before the adjacent section is applied. Zhejiang Bolei Coatings Co., Ltd. recommends working in manageable sections, especially in warm weather, to ensure the Exterior Latex Paint fuses into a monolithic coating.

Film Thickness and Coverage Control

Achieving the correct Dry Film Thickness (DFT) is vital for the longevity of Exterior Latex Paint. Zhejiang Bolei Coatings Co., Ltd. recommends applying Exterior Latex Paint in two distinct coats. The first coat acts as the primary barrier, while the second coat ensures color uniformity and maximum UV protection. Attempting to apply Exterior Latex Paint too thickly in a single coat can lead to "mud cracking" or sagging.

Efficiency Comparison of Tools for Applying Exterior Latex Paint

| Metric |

Airless Spraying |

Rolling |

Brushing |

| Coverage Speed |

Extreme: Best for industrial sites |

High: Standard for residential walls |

Low: Reserved for trim and edges |

| Film Uniformity |

Superior: Mirror-like finish possible |

Good: Provides a slight "stipple" texture |

Average: Dependent on painter skill |

| Material Loss |

Higher: Due to overspray/drift |

Minimal: Very efficient usage |

Negligible: Zero waste |

| Substrate Penetration |

Moderate: Requires back-rolling on masonry |

High: Forces Exterior Latex Paint into pores |

Maximum: Excellent for rough surfaces |

FAQ

Q: Can Exterior Latex Paint be applied over existing oil-based coatings?

A: Yes, but only with specific preparation. Because Exterior Latex Paint is water-based, it will not naturally bond to the glossy, non-porous surface of old oil paint. Zhejiang Bolei Coatings Co., Ltd. recommends thoroughly sanding the surface to remove the gloss, followed by a high-adhesion universal primer before the final coats of Exterior Latex Paint are applied.

Q: How long must Exterior Latex Paint cure before it can withstand rain?

A: While Zhejiang Bolei Coatings Co., Ltd. Exterior Latex Paint may be touch-dry in 60 minutes, it remains vulnerable to water damage until the resins have fully coalesced. Generally, 4 to 8 hours of dry weather is required. However, for Exterior Latex Paint to achieve full chemical resistance and hardness, a curing period of 7 to 14 days is typical depending on the humidity.

Q: Why does some Exterior Latex Paint develop a "chalky" white residue?

A: Chalking is the result of the paint binder breaking down due to UV exposure, releasing the pigment as a powder. Zhejiang Bolei Coatings Co., Ltd. uses 100% acrylic binders in its premium Exterior Latex Paint to prevent this. Cheap, vinyl-based Exterior Latex Paint is much more prone to chalking, which eventually leads to the total failure of the coating.

Performance Index: Expected Life of Exterior Latex Paint in Various Climates

| Climatic Environment |

Expected Service Life |

Recommended Inspection |

Key Maintenance Task |

| Arid / Temperate |

8 - 12 Years |

Every 5 years |

Basic surface washing to remove dust |

| High Humidity / Tropical |

6 - 8 Years |

Every 3 years |

Application of supplemental biocide wash |

| Coastal / Salt-Air |

5 - 7 Years |

Every 2 years |

Freshwater rinsing to prevent salt buildup |

| High Altitude (High UV) |

5 - 8 Years |

Every 4 years |

Monitoring for sheen loss and pigment fade |

Q: What is the correct way to thin Exterior Latex Paint for spray application?

A: Thinning should be kept to a minimum. Zhejiang Bolei Coatings Co., Ltd. suggests that Exterior Latex Paint should not be thinned by more than 10% with clean water. Excessive water breaks down the resin-to-pigment ratio, which will compromise the durability, hide, and sheen of the Exterior Latex Paint. Always stir the Exterior Latex Paint mechanically after adding water.

English

English

ENG

ENG

English

English