Founded in 1997, Zhejiang Bolei Coatings Co., Ltd. is a subsidiary of Bolei Industrial Group, with multiple subsidiaries engaged in coatings manufacturing, construction services, new material development, and international trade.

As a professional paint manufacturer based in China, we specialize in anti-corrosion coatings, fireproof coatings, emulsion paints, epoxy floor paints, and JS waterproof paints, widely applied in both industrial and construction sectors.

With advanced production facilities, a strict quality control system, and a stable raw material supply chain, we deliver high-quality and cost-competitive coating products and engineering solutions to our clients worldwide.

Fireproof Coatings

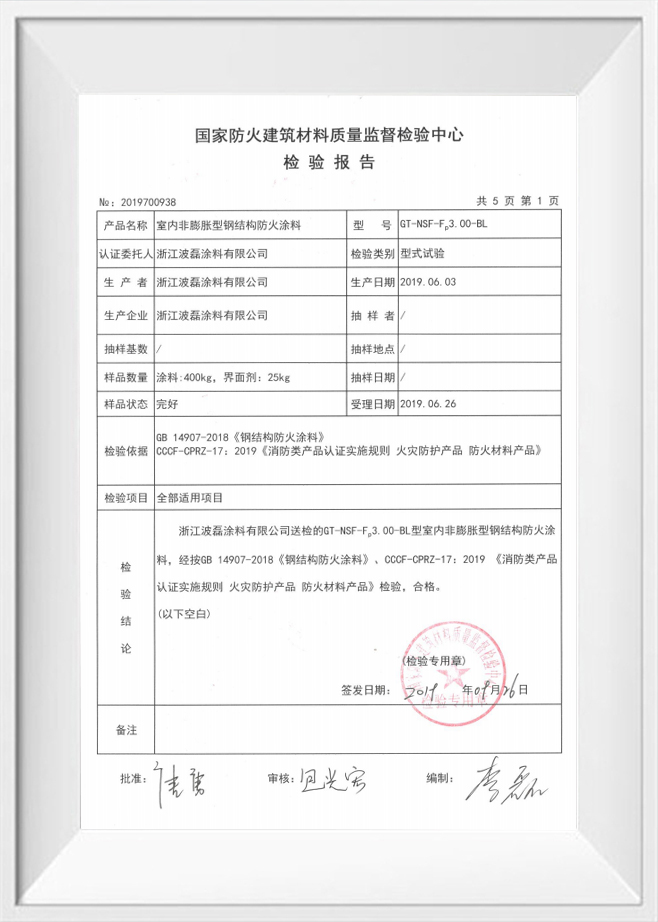

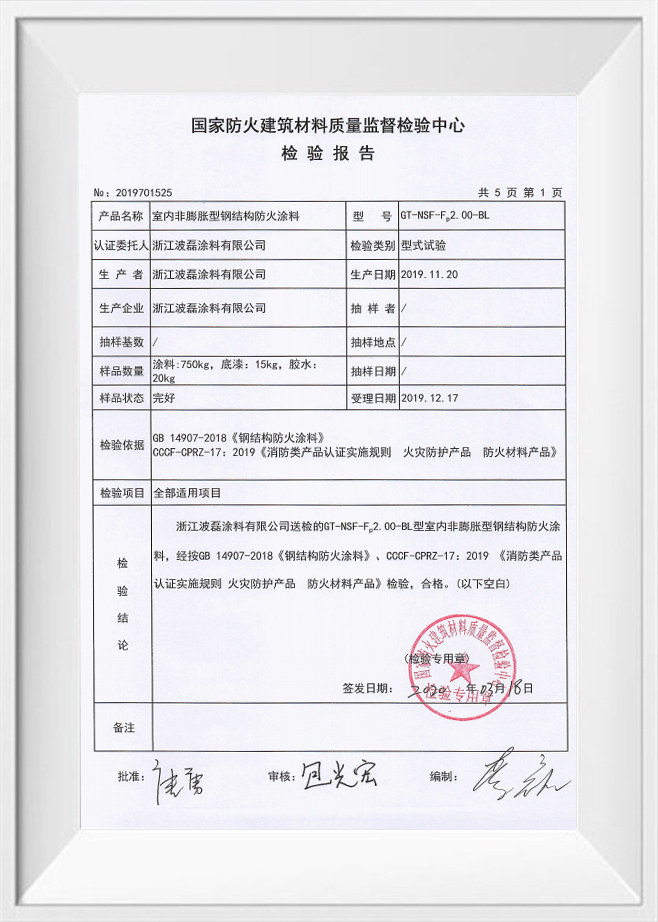

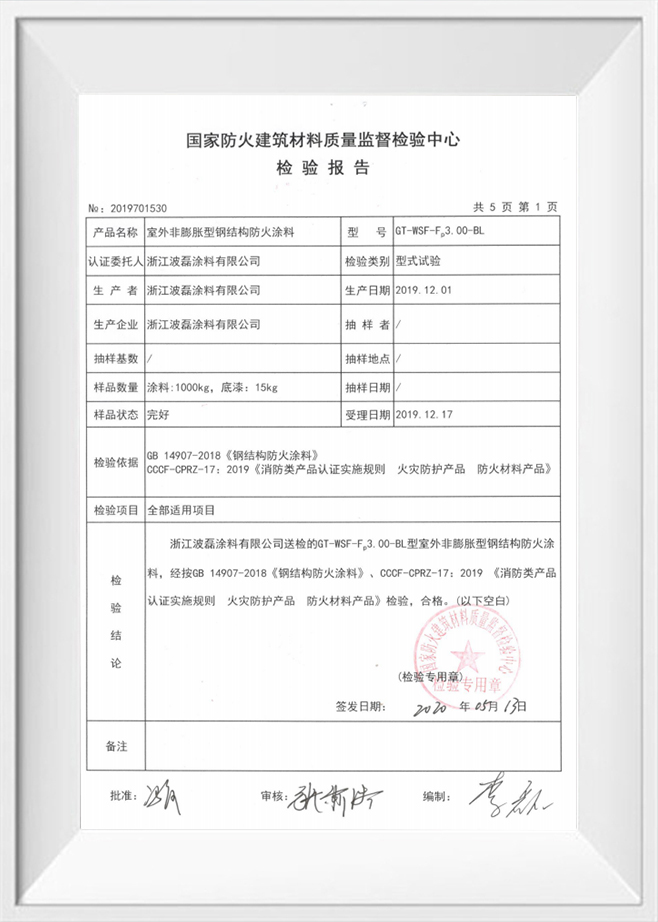

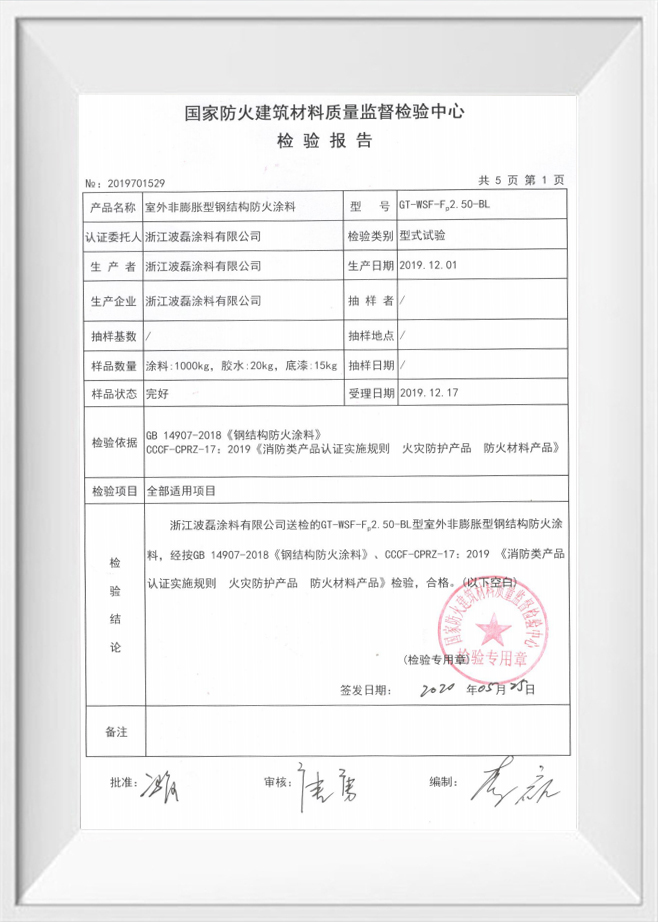

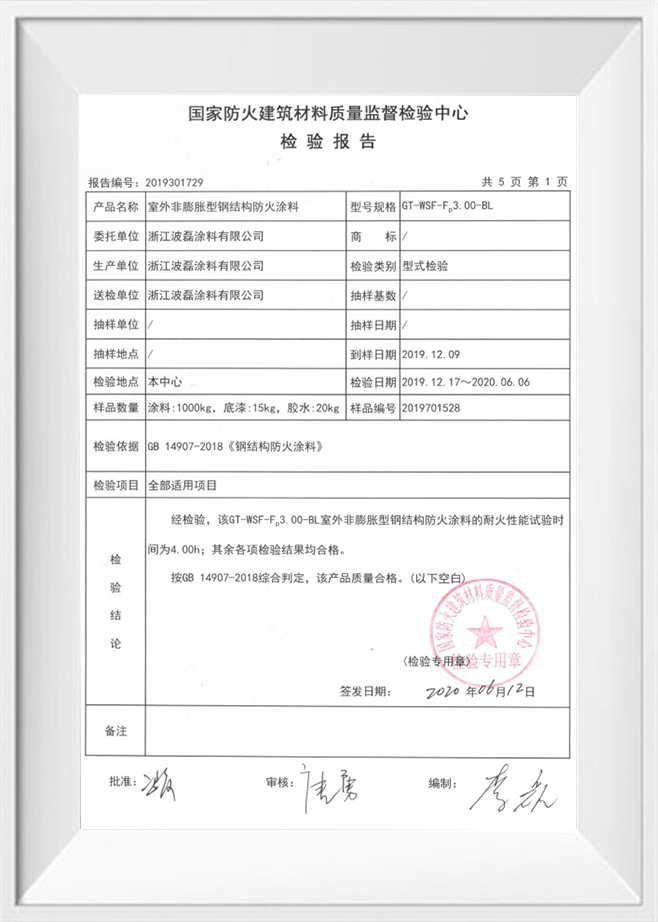

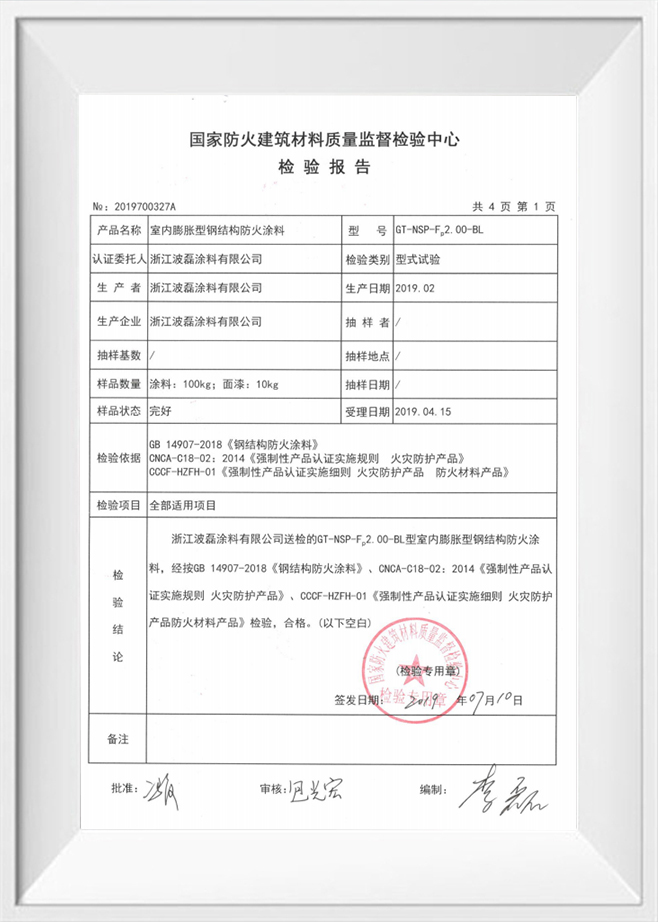

Our Fireproof Coatings provide essential fire resistance for steel structures and industrial facilities, delaying structural failure during fire and ensuring safety. We offer both Intumescent (Ultra-Thin) and Non-Intumescent (Thick Film) Coatings, all certified with comprehensive national fire test reports.

Applications

Steel Structures: High-rise buildings, factories, exhibition centers, airports, bridges

Energy & Infrastructure: Power plants, petrochemical facilities, tanks, tunnels

Public Buildings: Malls, theaters, hospitals, schools

Special Projects: Wind power, shipyards, landmark constructions

Services

Customized fireproofing solutions (30–180min ratings)

Full technical support from preparation to application

Complete certification and test documentation

Reliable delivery to meet project schedules

Advantages

Complete product range: intumescent & thick Coatings

Certified with full national test reports

High performance: durable fire resistance and strong adhesion

Strong reputation: trusted in landmark projects since 1997

Proven expertise with decades of experience

-

An Anti-Corrosive Primer is a specialized type of coating specifically formulated to protect metal surfaces from corrosion, rust, and other forms of degradation caused by exposure to moisture, oxygen,...

READ MORE -

Today, we have successfully developed an environmentally friendly and highly durable anti-corrosion paint for steel structures. This series of products integrates cutting-edge nanocomposite technology...

READ MORE -

In recent years, with the upgrading of consumption and the deepening of the country's "dual carbon" strategy, China's latex paint industry is undergoing a profound paradigm shift. The focus of industr...

READ MORE -

With the in-depth advancement of the national "dual carbon" strategy and the continuous improvement of building quality requirements, the polymer cement (JS) waterproof coating industry, which is a co...

READ MORE -

Today, Zhejiang Bolei Industrial Group Co., LTD., which enjoys a high reputation in the field of building safety and protection, grandly announced the launch of its newly developed high-performance fi...

READ MORE

What are Fireproof Coatings and Their Core Value

Definition and Function of Fireproof Coatings

Fireproof Coatings are specialized functional materials applied to the surfaces of buildings and industrial facilities. Their core function is to form a solid fire barrier through physical isolation or chemical reactions when a fire occurs, thereby delaying the time it takes for the substrate to reach its critical temperature.

As a leading global coating solutions provider, Zhejiang Bolei Coatings Co., Ltd. is committed to developing high-performance Fireproof Coatings. We understand that in extreme fire environments, every minute of structural integrity is vital to life safety. Therefore, our products are not just coverings; they are an indispensable part of Passive Fire Protection (PFP) systems.

The Foundation of Building Safety

In modern architectural and industrial design, the application of Fireproof Coatings has become a rigid requirement. Its core value is reflected in:

- Protecting Structural Strength: Preventing steel structures from losing load-bearing capacity and collapsing under high temperatures.

- Winning Evacuation Time: Gaining critical golden minutes for personnel evacuation and fire rescue.

- Reducing Asset Loss: Limiting the spread of fire to protect expensive industrial equipment and building main bodies.

Difference Between Fireproof and Flame Retardant Coatings

Many clients confuse Fireproof Coatings with general flame retardant coatings. The following table shows the essential differences in performance parameters:

| Performance Parameter | Fireproof Coatings | Flame Retardant Coatings |

|---|---|---|

| Core Objective | Maintain structural integrity, prevent collapse | Reduce surface flammability, stop flame spread |

| Fire Resistance Time | Usually 0.5 to 4 hours | Only a few minutes or just prevent ignition |

| Coating Thickness | Thick (customized per fire rating) | Thin (similar to decorative paint) |

| Application Object | Load-bearing steel, cables, wood structures | Fabrics, wallpaper, decorative panels |

| Thermal Reaction | Forms thick carbonized or ceramic layer | Releases suppressant gas or thin char layer |

Zhejiang Bolei Coatings Co., Ltd. relies on advanced production facilities and strict quality control systems to ensure that every batch of Fireproof Coatings meets and exceeds international standards in simulated fire tests.

Main Categories of Fireproof Coatings

In practical engineering applications, Fireproof Coatings are mainly divided into two categories based on their fire protection principles. Zhejiang Bolei Coatings Co., Ltd. has developed a full range of products in both areas to meet diverse needs.

Intumescent Fireproof Coatings

This is the most widely used type of Fireproof Coatings. It maintains a thin layer at room temperature, but upon fire exposure, the internal components react chemically and expand rapidly to form a thick carbonaceous foam layer.

- Advantages: Thin coating, lightweight, does not affect the aesthetic lines of the building.

- Applicable Scenarios: Exposed steel structures, stadiums, airport terminals, and commercial centers.

- Technical Features: Zhejiang Bolei Coatings Co., Ltd. produces intumescent Fireproof Coatings with extremely high expansion ratios and bonding strength.

Cementitious Fireproof Coatings (Non-Intumescent)

These Fireproof Coatings are usually based on inorganic insulating materials such as cement, gypsum, expanded vermiculite, or sepiolite. They do not rely on expansion but provide a physical insulation barrier through their low thermal conductivity.

- Advantages: Excellent weather resistance, long fire resistance time, and relatively low cost.

- Applicable Scenarios: Petrochemical facilities, tunnels, underground garages, and hidden engineering projects.

Water-based vs. Solvent-based Fireproof Coatings

- Water-based Fireproof Coatings: Uses water as a diluent, low VOC, non-toxic, and environmentally friendly—the first choice for green buildings.

- Solvent-based Fireproof Coatings: Offers stronger weather resistance and frost resistance, suitable for outdoor and harsh industrial environments.

Performance Comparison of Different Types

| Performance Index | Intumescent Fireproof Coatings | Cementitious Fireproof Coatings |

|---|---|---|

| Typical Thickness | 1mm - 5mm | 10mm - 50mm |

| Fire Rating (h) | 0.5 - 2.5 hours | 2.0 - 4.0+ hours |

| Decoration | Excellent, can be top-coated | Poor, granular or rough surface |

| Application Method | Spray, roller, or brush | Dedicated high-power sprayer |

| Weather Resistance | Good (indoor types need topcoat) | Extremely strong, water/moisture resistant |

| Structural Load | Extremely light | Heavy, must consider load limits |

As a core member of Bolei Industrial Group, Zhejiang Bolei Coatings Co., Ltd. provides standardized products and customized formula R&D for specific environmental challenges like high humidity or salt spray.

Working Principle of Fireproof Coatings

Understanding the mechanism of Fireproof Coatings is crucial for selection. The core goal is to slow down the heat transfer from external fire sources to the substrate.

Thermo-chemical Reaction Process

For intumescent Fireproof Coatings, the process starts when temperatures reach 200°C to 300°C:

- Softening: The polymer binder softens into a viscous fluid.

- Gas Release: Foaming agents decompose to release non-combustible gases that expand the coating.

- Carbonization: Carbonizing agents form a stable, porous char layer under acid catalysis, which blocks thermal radiation.

Physical Barrier Formation

Non-intumescent Fireproof Coatings rely on:

- Low Thermal Conductivity: Utilizing the natural insulation of vermiculite or perlite.

- Endothermic Reaction: Some coatings contain crystalline water that evaporates at high temperatures, absorbing heat and cooling the substrate.

Key Thermal Performance Comparison

| Thermal Parameter | Intumescent Fireproof Coatings | Cementitious Fireproof Coatings |

|---|---|---|

| Initial Reaction Temp | 200°C - 250°C | No specific trigger point |

| Thermal Conductivity | ~ 0.02 - 0.05 W/(m·K) (after char) | ~ 0.10 - 0.25 W/(m·K) |

| Expansion Ratio | 20 - 50 times | 1.0 - 1.1 times (stable) |

| Thermal Stability | High (remains intact at 1000°C) | High (resistant to thermal shock) |

| Oxygen Index (LOI) | > 35% | Non-combustible (Class A) |

Zhejiang Bolei Coatings Co., Ltd. has specially enhanced the adhesion design, ensuring our Fireproof Coatings stay tightly wrapped around the substrate even during thermal deformation.

Application Fields of Fireproof Coatings

Commercial Buildings and Skyscrapers

Used mainly for protecting exposed or hidden steel beams and columns in airports, stadiums, and high-rises.

- Focus: High fire rating combined with aesthetics and environmental safety.

- Solution: Zhejiang Bolei Coatings Co., Ltd. provides high-performance water-based products with 2+ hour fire ratings.

Oil & Gas Industry

Facing hydrocarbon fires that reach 1000°C within minutes.

- Focus: Resistance to thermal shock and high corrosion.

- Solution: Our heavy-duty anti-corrosion Fireproof Coatings are designed for offshore platforms and refineries.

Tunnels and Transportation

Tunnels accumulate heat quickly and produce dense smoke.

- Focus: Moisture resistance, aging resistance, and low smoke density.

- Solution: Cementitious tunnel-specific coatings from Zhejiang Bolei Coatings Co., Ltd. ensure long-term stability without toxic fumes.

Application Environment Comparison Table

| Scenario | Recommended Type | Core Evaluation Metric | Corrosion Class |

|---|---|---|---|

| High-rise Buildings | Intumescent | Adhesion, Topcoat compatibility | C1 - C2 |

| Sea Bridges/Docks | Epoxy-based Fireproof | Salt spray/Chemical resistance | C5 |

| Subways/Tunnels | Cementitious | Water resistance, Vibration resistance | C3 - C4 |

How to Select the Right Fireproof Coatings

Fire Resistance Time Requirements

- F1.00/1.50h: For secondary support members in general buildings.

- F2.00/3.00h: For load-bearing columns and beams in high-rises or industrial plants.

- Zhejiang Bolei Coatings Co., Ltd. offers products ranging from 0.5 to 4 hours of protection.

Substrate and Exposure Factors

Steel structures require a focus on anti-corrosion and primer compatibility. Outdoor environments require UV, water, and freeze-thaw resistance. Zhejiang Bolei Coatings Co., Ltd. develops specific exterior grades for these harsh conditions.

Selection Parameter Table

| Dimension | Interior Steel (Hidden) | Exterior Steel (Exposed) | High-Risk Industrial |

|---|---|---|---|

| Preferred Type | Intumescent/Cementitious | Solvent-based Intumescent | Epoxy or Cementitious |

| Fire Limit (h) | 1.0 - 2.0 h | 2.0 - 3.0 h | 3.0 - 4.0 h |

| Adhesion (MPa) | >= 0.15 | >= 0.30 | >= 0.50 |

| Durability | Standard | High (Rain/UV resistant) | Extreme (Chemical resistant) |

Compliance and Certification

Ensure products meet standards like GB 14907, ASTM E119, or EN 13381. Zhejiang Bolei Coatings Co., Ltd. is ISO 9001 certified and provides authoritative test reports for all products.

Application and Maintenance

Surface Preparation and Environment

- Cleaning: Steel should reach Sa 2.5 grit blasting standards.

- Control: Apply between 5°C and 35°C, with humidity below 85%.

Construction Parameter Monitoring

| Monitoring Item | Intumescent Fireproof Coatings | Cementitious Fireproof Coatings |

|---|---|---|

| Per Layer Thickness | WFT 0.5 - 1.0mm | 5 - 10mm |

| Recoat Interval | ~ 24 hours | 12 - 24 hours |

| Theoretical Coverage | ~ 1.5 - 2.0 kg/sqm (per mm) | ~ 1.0 - 1.2 kg/sqm (per mm) |

| Tooling | Airless spray, brush | Dedicated sprayer, trowel |

Maintenance and Repair

Establish a regular inspection system to check for mechanical damage or environmental degradation. Use Zhejiang Bolei Coatings Co., Ltd. products for localized repairs to maintain the fire rating integrity.

FAQ

Q: Can all Fireproof Coatings be used outdoors?

A: No. Interior types will fail if exposed to UV and rain. Zhejiang Bolei Coatings Co., Ltd. offers specific exterior grades that passed accelerated aging tests.

Q: Is there a direct ratio between thickness and fire time?

A: Generally, yes. See our typical intumescent parameters:

| Fire Rating | Recommended DFT | Approx. Usage |

|---|---|---|

| 1.0 Hour | 0.8 - 1.2 mm | 1.5 - 2.0 kg/sqm |

| 2.0 Hours | 2.5 - 3.5 mm | 4.5 - 5.5 kg/sqm |

Q: Why does cracking occur after construction?

A: Usually due to applying one layer too thick or poor surface cleaning. Follow the "thin layers, multiple coats" principle recommended by Zhejiang Bolei Coatings Co., Ltd..

Q: Can a topcoat be applied over Fireproof Coatings?

A: Yes, for aesthetics or weatherproofing. Ensure chemical compatibility so it doesn't inhibit the expansion of the Fireproof Coatings. We provide integrated primer-midcoat-topcoat systems.

Q: What is the service life of Fireproof Coatings?

A: In standard environments, Zhejiang Bolei Coatings Co., Ltd. products typically last 10 to 15 years before a performance re-evaluation is recommended.

English

English

ENG

ENG

English

English