Thick Non-intumescent Fireproof Coatings: Basic Definition and Characteristics

Thick Non-intumescent Fireproof Coatings are specialized safety materials designed to provide a long-term, stable thermal barrier for steel structures. Unlike intumescent coatings that rely on chemical reactions to produce a carbonized layer, these coatings delay heat transfer to the substrate through their physical thickness and the low thermal conductivity of inorganic materials.

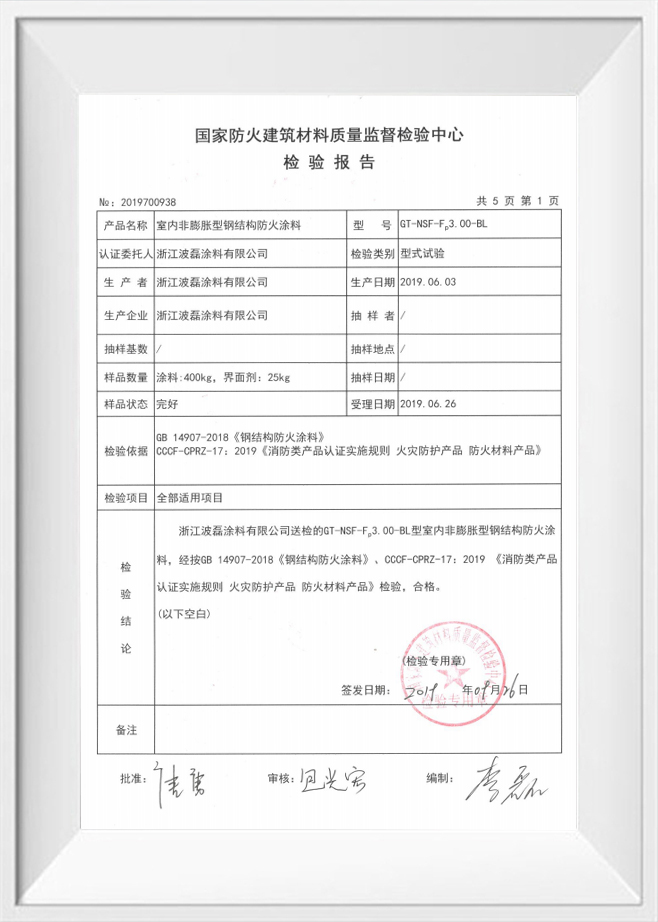

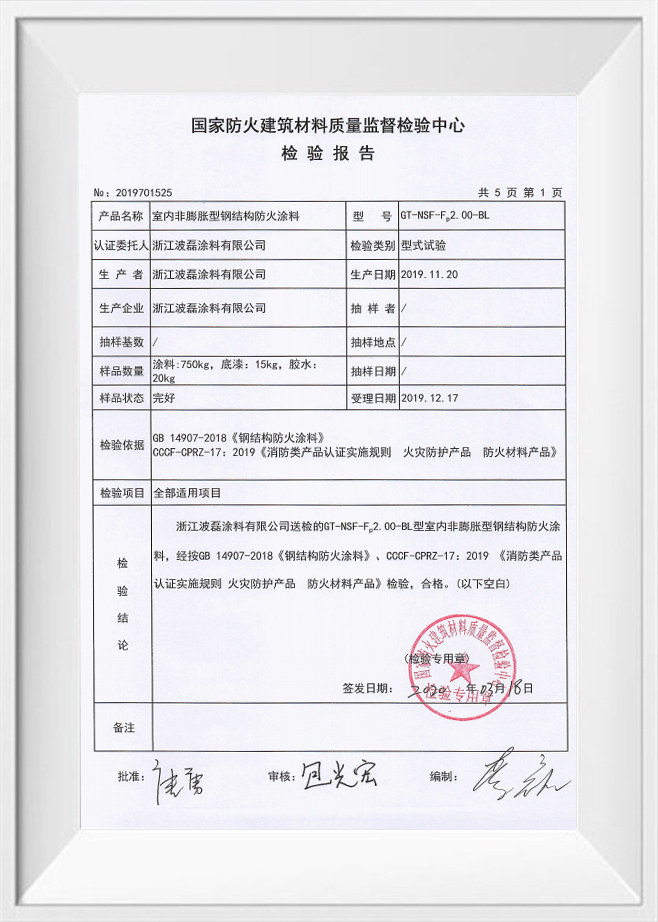

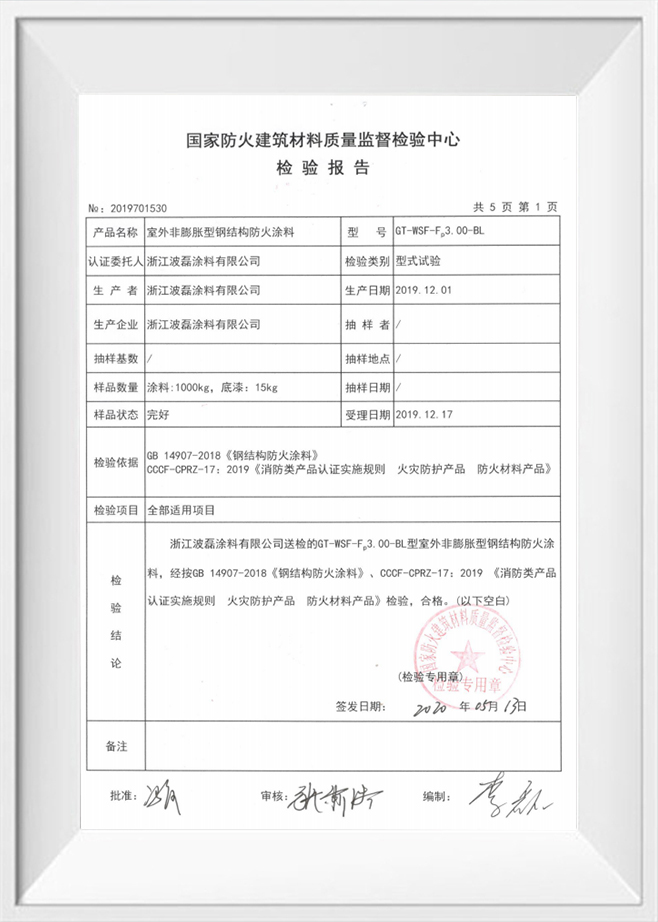

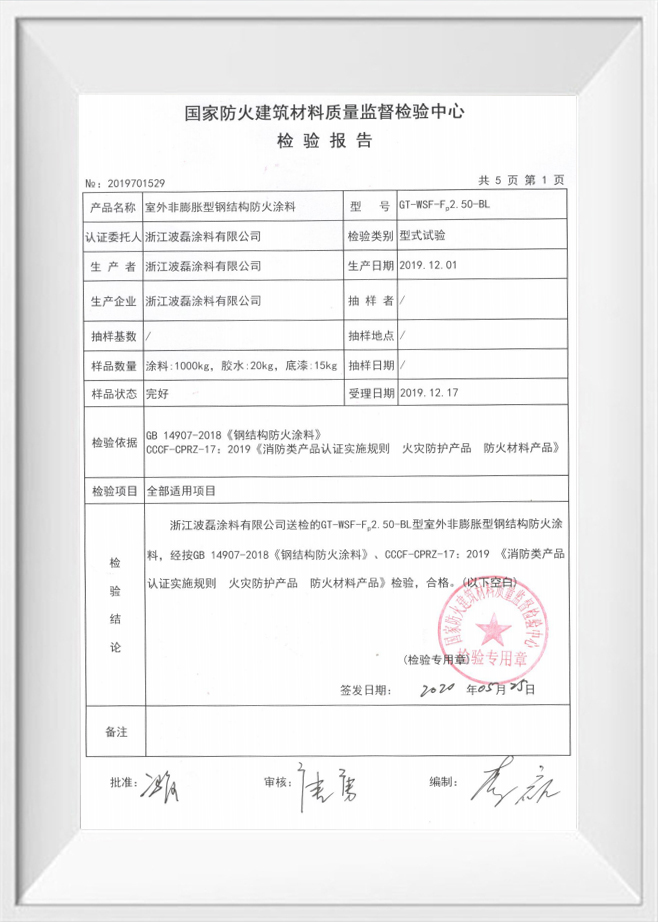

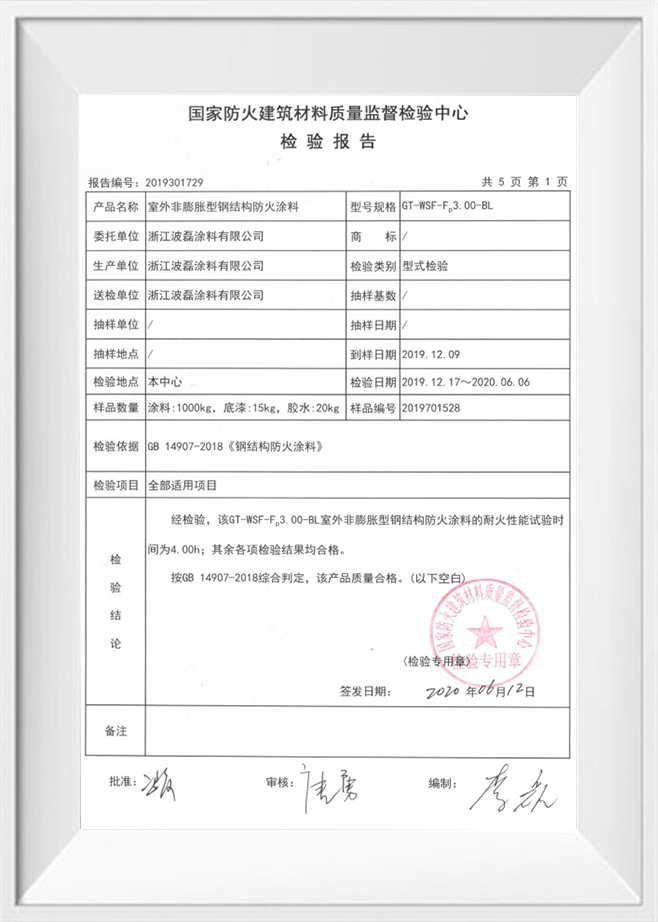

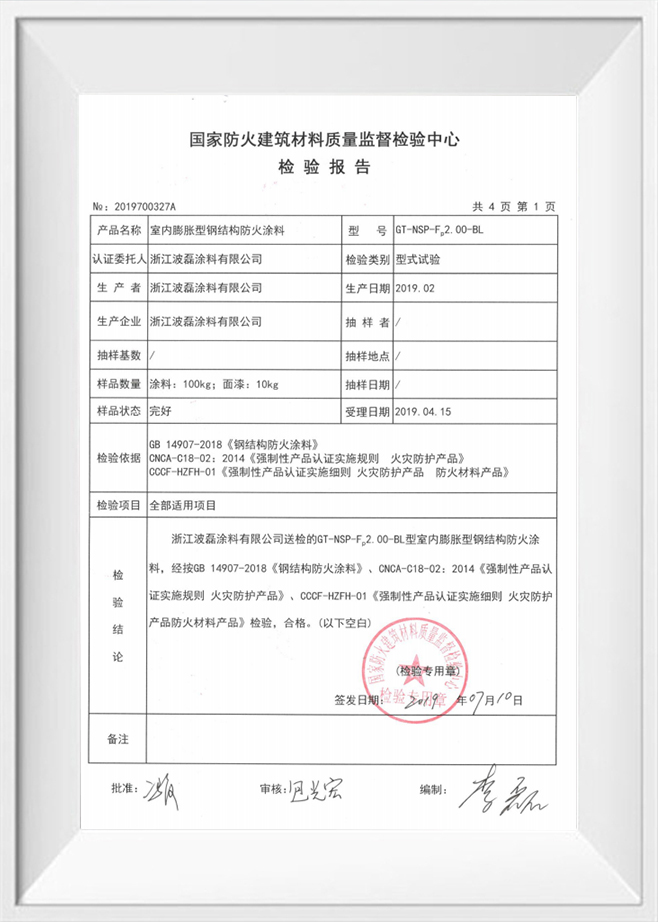

As a leading supplier in the industry, Zhejiang Bolei Coatings Co., Ltd. utilizes its deep expertise in material science to optimize the formulation of these coatings, ensuring exceptional structural stability when facing extreme high-temperature fires.

Core Mechanism: Thermal Barrier Effect

The protection logic of Thick Non-intumescent Fireproof Coatings is based on physical shielding. When a fire occurs, the coating does not undergo significant volume changes. Instead, it relies on a uniformly distributed microporous structure and refractory aggregates to form a solid physical wall. This mechanism ensures that even under continuous high temperatures for long durations, such as over 3 hours, the coating remains tightly adhered to the steel surface, preventing structural collapse.

Composition and Technical Advantages

Zhejiang Bolei Coatings Co., Ltd. produces Thick Non-intumescent Fireproof Coatings using a strictly selected raw material system to ensure high product quality:

Inorganic Binders: High-strength silicate or aluminate materials are used to ensure the coating does not pulverize or fall off at high temperatures.

Lightweight Insulating Aggregates: High-purity expanded vermiculite and perlite are selected, providing extremely low thermal conductivity.

Reinforcing Fibers: Special alkali-free glass fibers or anti-crack fibers are added to significantly improve the impact resistance and seismic performance of the coating.

Key Performance Parameter Comparison

To provide a clearer understanding of the technical standards for Thick Non-intumescent Fireproof Coatings, the following table compares these products with standard fireproof coatings:

| Performance Metric |

Thick Non-intumescent Fireproof Coatings |

Standard Intumescent Coatings |

| Thermal Conductivity |

Low (≤ 0.10 W/m·K) |

Moderate (≥ 0.15 W/m·K) |

| Fire Resistance Rating |

Up to 2.0 - 4.0 hours |

Usually 0.5 - 2.0 hours |

| State Under Heat |

Physically stable, no expansion |

Rapid expansion into carbon layer |

| Service Life |

20-30 years, stable properties |

5-10 years, prone to degradation |

| Smoke Toxicity |

Non-toxic, smoke-free (inorganic) |

May produce smoke or pungent gas |

| Bonding Strength |

High (≥ 0.15 MPa) |

Moderate (≥ 0.20 MPa) |

Industry-Leading Manufacturing Assurance

Zhejiang Bolei Coatings Co., Ltd., supported by the strong industrial chain of Bolei Industrial Group, implements strict quality control from raw material supply to finished product manufacturing. Our Thick Non-intumescent Fireproof Coatings not only meet national standards but also pass multiple pressure tests simulating extreme fire environments, providing high-quality and cost-competitive engineering solutions for industrial and construction projects worldwide.

Main Performance Indicators of Thick Non-intumescent Fireproof Coatings

When evaluating fire protection schemes for steel structures, the physical and chemical indicators of Thick Non-intumescent Fireproof Coatings are core to measuring safety. Zhejiang Bolei Coatings Co., Ltd. ensures that every batch maintains stable performance in extreme environments through advanced production equipment and rigorous quality control.

Core Physical Performance Indicators

The value of Thick Non-intumescent Fireproof Coatings lies in their stability under high heat loads:

Dry Density: Usually controlled between 450 to 550 kg/m3. A lighter density effectively reduces the additional load on high-rise steel structures, which is a key technical focus for the R&D team at Zhejiang Bolei Coatings Co., Ltd.

Thermal Conductivity: Maintained at 0.08 - 0.10 W/m·K at room temperature. Low conductivity is the technical prerequisite for achieving a fire resistance rating of over 3 hours.

Compressive Strength: The material must withstand physical impacts during construction and maintenance. Our products balance fire performance with excellent hardness.

Durability and Environmental Adaptability

Because Thick Non-intumescent Fireproof Coatings are often used in large industrial facilities or concealed engineering works, long-term stability is vital.

Water and Moisture Resistance: The coating does not soften, blister, or peel off even in high-humidity environments like underground engineering.

Freeze-Thaw Resistance: After multiple freeze-thaw cycles, the coating maintains its original bonding strength without cracking.

Seismic Resistance: Under industrial vibration or seismic impact, the solutions provided by Zhejiang Bolei Coatings Co., Ltd. ensure the coating remains tightly bonded to the steel substrate.

Detailed Parameter Comparison: Coating Requirements for Different Fire Durations

The thickness of Thick Non-intumescent Fireproof Coatings directly determines the fire resistance limit. The following table shows the correspondence between typical parameters:

| Fire Rating (Hour) |

Recommended Thickness (mm) |

Weight Load (kg/m2) |

Technical Suggestion |

| 1.5 Hours |

15 - 20 |

Approx. 7.5 - 10.0 |

Suitable for secondary beams |

| 2.0 Hours |

25 - 30 |

Approx. 12.5 - 15.0 |

Suitable for main industrial frames |

| 3.0 Hours |

35 - 45 |

Approx. 17.5 - 22.5 |

Suitable for super high-rise cores |

| 4.0 Hours |

Above 50 |

Approx. 25.0+ |

For high-security special warehouses |

Why Choose Our Technical Solutions?

As a core member of Bolei Industrial Group, Zhejiang Bolei Coatings Co., Ltd. not only provides standardized Thick Non-intumescent Fireproof Coatings but also customizes performance parameters for different climate zones using our stable raw material supply chain.

Construction Technology and Process

The final protective effect of Thick Non-intumescent Fireproof Coatings depends not only on material quality but also on thickness control and interface bonding during construction. Zhejiang Bolei Coatings Co., Ltd. has summarized a standardized construction process to ensure the coating does not peel or crack under high-intensity fires.

Surface Preparation

Before applying Thick Non-intumescent Fireproof Coatings, the steel surface must reach specific cleanliness:

Rust Removal: It is recommended to reach Sa 2.5 (sandblasting) or St 3 (manual cleaning).

Primer Compatibility: Ensure the steel structure is coated with anti-corrosion primer and is completely dry. The technical team at Zhejiang Bolei Coatings Co., Ltd. provides matching primer suggestions.

Preparation and Mixing

The mixing process must be strictly controlled due to the lightweight mineral aggregates in Thick Non-intumescent Fireproof Coatings:

Ratio Control: Strictly follow the water-to-powder ratio in the product manual using mechanical stirring.

Maturation Time: Let the mixture stand for 5-10 minutes after stirring to allow polymer additives to fully dissolve and activate adhesion.

Layered Construction Process

Thick coatings cannot be sprayed all at once to avoid sagging due to weight.

Base Coat: Thickness is controlled at 3-5 mm to establish the bonding interface with the substrate.

Subsequent Layers: Each following layer should not exceed 10 mm. Wait for the previous layer to be touch-dry before the next application.

Mesh Reinforcement: When the design thickness of Thick Non-intumescent Fireproof Coatings is ≥ 25 mm, Zhejiang Bolei Coatings Co., Ltd. suggests embedding alkali-resistant glass fiber mesh.

Construction Key Parameter Comparison Table

| Construction Step |

Requirement |

Technical Standard |

| Ambient Temperature |

5°C to 35°C |

No construction below 5°C or in rain |

| Relative Humidity |

≤ 85% |

Ensure normal water evaporation |

| Spraying Pressure |

0.4 to 0.6 MPa |

Ensure uniform atomization |

| Interval Time |

24 hours |

Must reach surface dry state |

| Curing Period |

At least 28 days |

To reach final design strength |

Quality Inspection and Acceptance

Zhejiang Bolei Coatings Co., Ltd. emphasizes multi-point sampling inspection:

Thickness Testing: Use needle penetration or a thickness gauge to detect dry coating thickness.

Appearance Check: The coating should be uniform in color, without obvious cracks, hollows, or missed spots.

Key Application Scenarios

Thick Non-intumescent Fireproof Coatings are the preferred choice for critical infrastructure due to their stability and adaptability to harsh environments. Zhejiang Bolei Coatings Co., Ltd. provides customized engineering solutions for various global industrial needs.

Petrochemical and Energy Facilities

In the petrochemical industry, fires often manifest as high-intensity hydrocarbon fires.

Application Characteristics: Refineries and LNG tank supports need to withstand extreme heat loads.

Technical Advantages: Thick Non-intumescent Fireproof Coatings have high heat capacity. Products from Zhejiang Bolei Coatings Co., Ltd. perform excellently under the HC curve, protecting steel structures from losing bearing capacity at temperatures above 1100°C.

High-rise and Super High-rise Steel Frames

For buildings exceeding 100 meters, structural fire safety is paramount.

Application Characteristics: Main beams and columns usually require a fire rating of 3.0 hours or more.

Technical Advantages: Compared to intumescent coatings, thick coatings offer longer physical stability in concealed works, without worrying about fire performance attenuation caused by the aging of organic components.

Tunnels and Underground Engineering

Tunnels are enclosed and humid, and vehicle fires produce extremely high-temperature smoke.

Application Characteristics: Coatings must be fireproof and possess excellent water and moisture resistance.

Technical Advantages: The inorganic nature of Thick Non-intumescent Fireproof Coatings is naturally moisture-resistant. As a subsidiary of Bolei Industrial Group, we have significantly improved adhesion in humid environments through advanced material science.

Parameter Requirements by Application Scenario

| Scenario |

Fire Type |

Suggested Rating |

Key Performance Focus |

| Petrochem Pipe Rack |

Hydrocarbon (HC) |

2.0 - 4.0 h |

High-temp impact/Corrosion resistance |

| High-rise Main Column |

Cellulosic (A) |

3.0 h |

Lightweight/Strong bonding |

| Traffic Tunnel |

Tunnel Fire |

2.0 - 3.0 h |

Moisture resistance/No smoke |

Comparison with Intumescent Fireproof Coatings

Understanding the essential differences between Thick Non-intumescent Fireproof Coatings and intumescent coatings is vital. As a core product line of Zhejiang Bolei Coatings Co., Ltd., the thick coating scheme demonstrates irreplaceable reliability.

Physical Mechanism and Thermal Stability

Non-intumescent Type: The volume remains basically unchanged when heated, relying on a porous inorganic ceramic-like structure for insulation. This stability means the coating won't fall off due to severe airflow during a fire.

Intumescent Type: Relies on chemical reactions to produce an expanded carbon layer when heated.

Durability and Life Cycle

Since Thick Non-intumescent Fireproof Coatings produced by Zhejiang Bolei Coatings Co., Ltd. are mainly composed of inorganic lightweight minerals:

Anti-aging: Inorganic materials do not degrade over time like the organic resins in intumescent coatings, so fire performance can synchronize with the building's lifespan.

Maintenance-Free: Almost no periodic recoating or maintenance is required, saving customers significant long-term operating costs.

Comprehensive Performance Comparison Table

| Feature |

Thick Non-intumescent Fireproof Coatings |

Intumescent Fireproof Coatings |

| Principle |

Physical Insulation (Barrier) |

Chemical Expansion (Charring) |

| Thickness |

Typical 7 - 50 mm |

Typical 1 - 5 mm |

| Fire Rating |

Stable up to 3.0 - 4.0 h |

Usually for 0.5 - 2.0 h |

| Weatherability |

Excellent (UV/Moisture resistant) |

Prone to environmental aging |

| Smoke/Toxicity |

Inorganic, non-toxic, no smoke |

May produce pungent gases |

| Maintenance |

Extremely Low |

Medium to High |

Why Large Projects Prefer Thick Coatings

In projects involving Zhejiang Bolei Coatings Co., Ltd., engineers prefer specifying Thick Non-intumescent Fireproof Coatings for main structural frames. This is based on safety redundancy: thick coatings have stronger thermal inertia in the early stages of a fire. As part of Bolei Industrial Group, we use our R&D strengths to reduce the total weight load on structures while maintaining the stability of thick coatings.

FAQ

Q1: What is the typical construction thickness for Thick Non-intumescent Fireproof Coatings?

A: Thickness depends on the required fire rating. Generally, a 2.0-hour rating requires about 15-20 mm; a 3.0-hour rating or more requires 30 mm or higher. Zhejiang Bolei Coatings Co., Ltd. optimizes formulations to provide lower thermal conductivity at the same thickness.

Q2: Will the coating crack after construction?

A: Since these are cementitious or silicate-based materials, fine surface cracks may occur during drying shrinkage. As long as the crack width is less than 0.5 mm, it usually does not affect fire performance. Zhejiang Bolei Coatings Co., Ltd. adds reinforcing fibers to effectively improve crack resistance.

Q3: Why are thick coatings better than thin intumescent coatings for industrial environments?

A: The key lies in physical and chemical stability. The inorganic components of Thick Non-intumescent Fireproof Coatings are stable, have strong chemical resistance, and do not need to reach a specific temperature to trigger a reaction, providing constant physical insulation.

Q4: What are the humidity requirements for the construction environment?

A: During construction, relative humidity should be kept below 85%. Zhejiang Bolei Coatings Co., Ltd. reminds customers that excessive humidity slows water evaporation and affects the establishment of bonding strength.

Q5: Can this product be customized with specific colors or finishes?

A: The finished surface usually has a natural granular texture. For aesthetic needs, a compatible decorative topcoat can be applied after the fireproof coating is completely dry. As a professional manufacturer, Zhejiang Bolei Coatings Co., Ltd. also provides matching emulsion paints or high-performance anti-corrosion topcoats to ensure system compatibility.

English

English

ENG

ENG

English

English